Sublimation on fabrics opens up a world of possibilities for vibrant, long-lasting designs. Whether you’re a seasoned pro or just starting, mastering this technique can elevate your creations to new heights. In this comprehensive guide, we’ll explore everything you need to know to become a sublimation expert.

Understanding Sublimation: The Key to Vibrant Prints

Sublimation is a process where a solid substance bypasses the liquid phase and turns directly into a gas under specific conditions. When it comes to fabrics, sublimation ink transforms into a gas when heated, allowing it to penetrate the fabric fibers and create stunning, permanent prints.

The Sublimation Process

1. Preparing the Design

Before diving into the sublimation process, it is crucial to create or select a design suitable for sublimation printing. This can be done using graphic design software or by choosing from a wide range of pre-made designs available.

2. Choosing the Right Fabrics

Not all fabrics are suitable for sublimation printing. Polyester fabrics provide the best results due to their ability to absorb and retain the dyes. Cotton and other natural fibers, on the other hand, do not work well with sublimation.

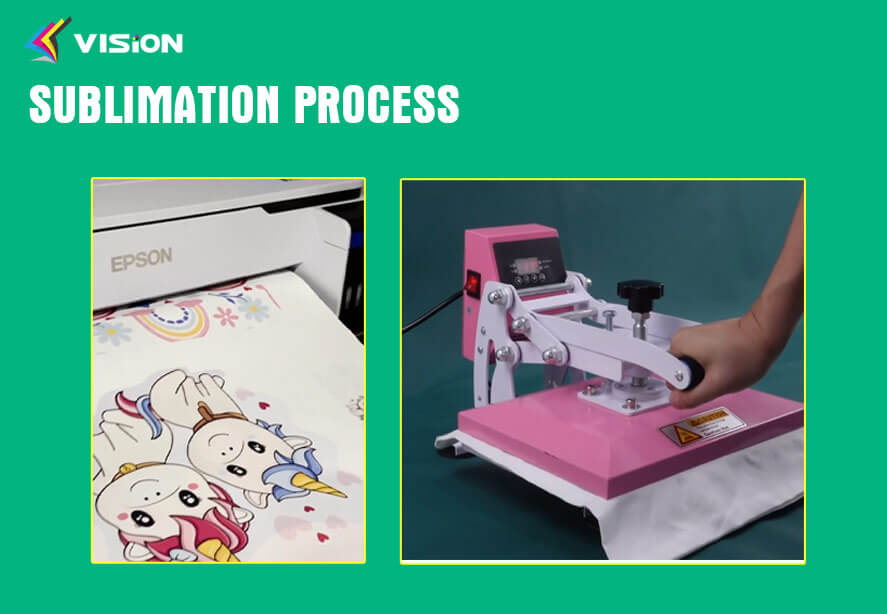

3. Printing with Sublimation Ink

Sublimation ink is specially formulated to convert from a solid to a gas state under heat and pressure. The design is printed onto a sublimation transfer paper using sublimation ink. It is essential to ensure that the printer and ink are compatible for optimal results.

Sublimation Process

4. Heat Transfer Process

The printed design on the transfer paper is placed onto the fabric, and heat is applied using a heat press machine. The heat causes the sublimation ink to turn into gas, which then penetrates the fabric’s fibers, bonding with them. This process ensures that the design becomes a permanent part of the fabric.

Related:

What sublimation paper is and its role in printing process

Sublimation Tools and Equipment

To achieve the best results in sublimation printing, it is essential to have the right tools and equipment. Here are some key items to consider:

1. Sublimation Printer

Investing in a high-quality sublimation printer is crucial for obtaining vibrant and accurate prints. Choose a printer that is compatible with sublimation ink and offers a high resolution for optimal results.

2. Sublimation Ink and Transfer Paper

Using sublimation-specific ink and transfer paper is essential for achieving excellent results. These materials are specially formulated to work together and provide vibrant and long-lasting prints.

3. Heat Press Machine

A heat press machine is used to apply heat and pressure during the sublimation process. Look for a heat press machine that offers precise temperature control and even distribution of heat for consistent results.

4. Fabric Preparation Tools

To ensure the best adhesion of the sublimation ink to the fabric, proper fabric preparation is necessary. Tools such as lint rollers and heat-resistant tape help remove any debris or wrinkles from the fabric before printing.

Why Choose Vision Sublimation Transfer Paper?

Tips for Successful Sublimation Printing

To achieve the best results in sublimation printing, consider the following tips:

1. Color Management

Understanding color management is crucial for accurate and vibrant prints. Calibrating your monitor, using color profiles, and performing regular color checks will help ensure consistent and accurate colors in your sublimation prints.

2. Heat and Pressure

Finding the right combination of heat and pressure is key to successful sublimation printing. Experiment with different settings and conduct test prints to determine the optimal heat and pressure for your specific fabrics and designs.

3. Fabric Testing

Before printing a large batch, it is advisable to conduct fabric testing. Test different fabrics and observe how they react to the sublimation process. This will help you determine which fabrics yield the best results and avoid any surprises during production.

Troubleshooting and Maintenance

Even with proper techniques and equipment, challenges may arise during the sublimation process. Here are some common issues and their solutions:

1. Uneven Prints

Uneven prints can occur due to uneven pressure or heat distribution. Ensure that your heat press machine is properly calibrated and apply even pressure throughout the printing process.

2. Fading Prints

Fading prints can be caused by low-quality ink or improper curing. Use high-quality sublimation ink and ensure that the printed fabric undergoes the recommended heat and pressure application for the required duration.

3. Ghosting

Ghosting refers to a faint image appearing on the fabric after printing. This can happen due to sublimation ink residue or improper transfer. Clean your heat press machine regularly and ensure that the transfer paper is properly aligned and in contact with thefabric during the heat transfer process.

4. Caring for Sublimated Fabrics

To maintain the longevity of sublimated fabrics, it is important to follow proper care instructions. Wash the fabrics in cold water, preferably on a gentle cycle, and avoid using harsh detergents or bleach. Additionally, avoid exposing sublimated fabrics to direct sunlight for extended periods to prevent fading.

Learn more: 3 Common problems and solutions of sublimation transfer paper

Exploring Advanced Sublimation Techniques

Once you have mastered the basics of sublimation printing, you can explore advanced techniques to take your designs to the next level. Some advanced techniques include:

1. Sublimation on Dark Fabrics

While sublimation is commonly associated with light-colored fabrics, it is possible to achieve vibrant prints on dark fabrics as well. Special sublimation inks and sublimation vinyl are available for this purpose, allowing you to create stunning designs on a wider range of fabrics.

Related:

A Guide to Sublimation Vinyl on Dark Cotton Fabric

How To Sublimate On Dark Shirts Using Vision Sublimation HTV?

2. Sublimation on Blends and Other Fabrics

Although polyester fabrics are most commonly used for sublimation printing, it is possible to achieve successful results on fabric blends and other materials. Conduct fabric testing and experiment with different settings to determine the best approach for sublimating non-polyester fabrics.

3. Sublimation on 3D Objects

Sublimation printing is not limited to flat fabrics. With the right equipment and techniques, you can transfer designs onto various 3D objects, such as mugs, phone cases, puzzles and keychains and more interesting projects. Explore sublimation-specific accessories and heat presses designed for 3D sublimation printing.

Mastering sublimation on fabrics opens up a world of creative possibilities in textile design and customization. By understanding the sublimation process, investing in the right tools and equipment, and implementing proper techniques, you can achieve vibrant and long-lasting prints on a wide range of fabrics. Remember to troubleshoot any issues that may arise and explore advanced techniques to further enhance your sublimation skills. With practice and creativity, you can unlock the full potential of sublimation printing and create stunning designs that stand out.