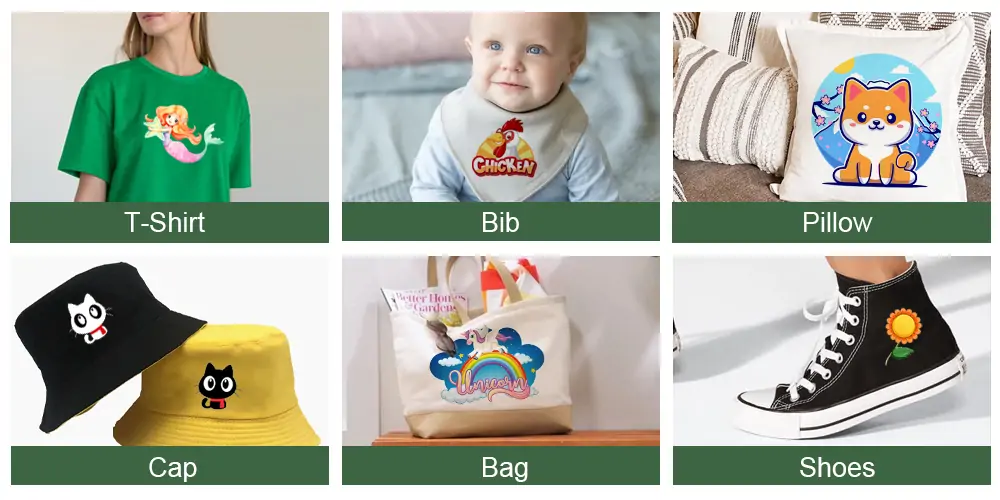

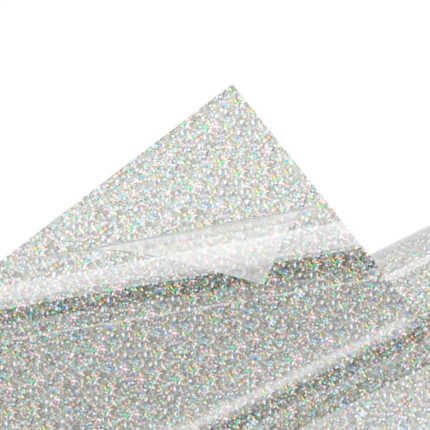

Printable heat transfer vinyl (PU) is the easiest way to achieve multi-color graphics on your garment. The high-definition pattern can be printed on the back of the printing film using an eco-solvent printer, and then the printed heat transfer vinyl is transferred to the transfer film through a cold laminating machine, and the PET glue on the bottom layer of the printing film is torn off. Transferred to garment fabric by heat press machine.

The printable HTV has vivid printing images, good color reproduction and soft and comfortable hand feeling.

printed heat press vinyl

Specifications

| Size | 50cm*25m |

| Thickness | 0.08~0.18mm |

| Package | 1 rolls/carton |

| Transfer Temperature | 150~160°C |

| Time | 10-15s |

| Transfer Pressure | Medium |

| Peel | Cold |

How to use printable transfer vinyl

![]() Print

Print

Print the heat transfer vinyl with eco-solvent printer;

Before printing, you must use “SignMaster” to add positioning points to the pattern.![]() Cut

Cut

Use the cutter plotter. It is recommended to set the knife pressure to 200g and the knife speed to 200~320mm/s;

Please adjust according to the actual situation.

![]() Weed

Weed

It is recommended to use hooks or other tools.

![]() Laminate

Laminate

It is recommended to use a low-viscosity transfer tape;

Using a laminator can effectively reduce the air bubbles between the heat transfer vinyl and the transfer tape.

![]() Heat Transfer

Heat Transfer

It is recommended to preheat the T-shirt before heat transfer to remove the moisture or wrinkles;

Temperature: 160°C; Time: 10s; Pressure is slightly lower.

When the T-shirt cools down, slowly tear off the transfer tape.