Using dark transfer paper is a fantastic way to bring your designs to life on fabrics, but it can be frustrating when things don’t go as planned.

When the transfer doesn’t stick properly, it can result in a faded or incomplete design, diminishing the overall appearance of your creation. Let’s delve into the potential causes behind this issue and explore effective solutions.

Possible Reasons for Non-Adherence

Dark transfer paper not sticking can be attributed to several factors, each of which plays a pivotal role in the outcome of your heat transfer process. Let’s explore these reasons and understand how to overcome them:

Improper Fabric Choice

Dark transfer paper is designed to work best on specific fabric types. If you’re using a fabric that isn’t compatible with the paper, it can lead to poor adhesion. Fabrics with high synthetic content, such as polyester, tend to yield better results with dark transfer paper. Natural fabrics like cotton might not provide the necessary surface for proper adhesion.

Inadequate Washing and Drying

Preparation is key to a successful transfer. Make sure to wash and dry your fabric before applying the transfer. Washing helps eliminate any residues that might hinder the adhesive properties of the transfer paper. Drying the fabric ensures that there is no residual moisture that could affect the transfer process.

Incorrect Temperature and Pressure

Achieving the right temperature and pressure settings on your heat press is crucial. Too much heat or pressure can cause the adhesive to burn, while insufficient heat and pressure can result in incomplete transfer bonding. Follow the guidelines of transfer paper manufacturer for your specific transfer paper and fabric combination.

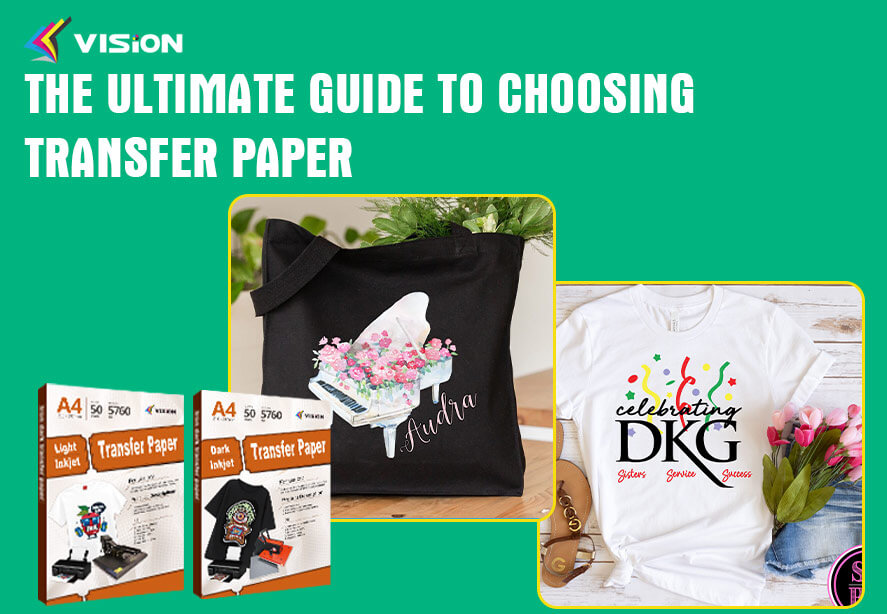

Poor Transfer Paper Quality

Not all transfer papers are created equal. Opt for high-quality transfer paper from reputable brands. Vision is your best transfer paper supplier, contact us anytime for Free sample to test. Cheaper alternatives might not have the same adhesive properties, leading to issues with sticking. Investing in quality paper can significantly improve your results.

Incorrect Handling

The way you handle the transfer paper during and after application matters. If you peel the paper too soon, the design might not fully adhere to the fabric. Allow the transfer to cool down before peeling off the backing paper. Gently peel the paper at a 180-degree angle to prevent damage.

Printer Quality: Low-quality inkjet printers or outdated printer cartridges might result in subpar ink transfer, affecting adhesion.

Peeling Technique: Incorrect peeling technique—whether peeling the transfer paper too quickly or too slowly—can impact the transfer’s success.

Heat Source: Using an uneven heat source, such as a household iron with uneven temperature distribution, can cause parts of the transfer not to adhere properly.

Troubleshooting and Solutions

Check Heat and Pressure: Ensure you’re using the recommended heat settings for your transfer paper and fabric. Use a heat press machine if possible for even pressure distribution.

Fabric Compatibility: Test the transfer paper on a small section of the fabric to check for compatibility before transferring the entire design.

Fabric Preparation: Wash the fabric to remove any sizing agents or chemicals that could hinder adhesion. Avoid using fabric softeners.

Printer Quality: Use a high-quality inkjet printer with fresh cartridges to achieve vibrant and well-saturated designs.

Peeling Technique: Follow the manufacturer’s instructions for peeling the transfer paper, allowing it to cool slightly before peeling.

Even Heat Distribution: If using an iron, make sure it’s set to the appropriate temperature and apply consistent pressure while moving the iron around the design.

Preventive Measures

Quality Products: Invest in high-quality dark transfer paper from reputable brands.

Fabric Selection: Opt for fabrics with a high cotton content for better adhesion results.

Fabric Testing: Always test the transfer on a scrap piece of fabric before applying it to your final project.

Follow Instructions: Carefully follow the instructions provided by the transfer paper manufacturer.

Dark transfer paper not adhering properly can be a frustrating experience, but with the right approach and troubleshooting steps, you can overcome this issue and achieve successful transfers. By ensuring proper heat, pressure, fabric preparation, and peeling technique, you can enjoy vibrant and long-lasting designs on your fabrics.

FAQs

Yes, but make sure to use an iron with even heat distribution and follow the recommended temperature settings.

Yes, fabrics with a coarse texture might pose challenges in achieving even adhesion.

It’s not recommended, as reheating the fabric could affect the quality of the transfer.

Dark transfer paper is specifically designed for dark fabrics. For light fabrics, use light transfer paper.

Store it in a cool, dry place away from direct sunlight to maintain its effectiveness.