When it comes to printing designs onto garments or fabrics, there are several methods available, each with their own set of advantages and disadvantages. In recent years, Direct-to-Film (DTF) has emerged as a popular alternative to traditional heat transfer methods. While both DTF and heat transfer have their benefits, there are some key differences that make DTF a preferable choice for some applications.

With the advent of direct-to-film (DTF) printing, a new breakthrough in T-shirt printing technology, many people first wonder what is so special about it? What does DTF offer that other printing technologies cannot? So many people want to know, the difference between DTF and thermal transfer printing? Which is better between the two?

DTF printing

DTF is a relatively new technology that involves printing designs onto a special film, which is then transferred onto the garment using heat and pressure. Unlike traditional heat transfer methods, DTF does not require a transfer paper or vinyl. Instead, the design is printed directly onto a special film that has a self-adhesive layer on the back. This film is then applied to the garment using heat and pressure, which melts the adhesive layer and fuses the design to the fabric.

3 advantages of DTF printing

One of the primary advantages of DTF over traditional heat transfer methods is the quality of the print. Because the ink is applied directly to the film rather than being absorbed by a transfer paper, the resulting image is much more vibrant and detailed. This is particularly true for designs with small details or intricate patterns. With DTF, you can achieve a level of detail that is simply not possible with traditional heat transfer methods.

Another advantage of DTF is the speed and efficiency of the process. Because there are fewer steps involved, DTF is generally faster than traditional heat transfer methods. With DTF, you can print and transfer a design in a matter of minutes, whereas traditional heat transfer methods can take significantly longer. This is particularly true for large designs or designs with multiple colors, which can be time-consuming to print and transfer using traditional heat transfer methods.

DTF also has some distinct advantages when it comes to durability. Because the ink is fused directly to the fabric, DTF prints are generally more resistant to fading, cracking, and peeling than traditional heat transfer methods. This makes DTF a great choice for applications where durability is a concern, such as athletic uniforms, workwear, or promotional items.

2 drawbacks of DTF printing

One of the potential drawbacks of DTF is the cost. Because DTF requires specialized equipment and materials, it can be more expensive than traditional heat transfer methods. However, the cost of DTF has come down in recent years, and there are now affordable options available for small businesses or hobbyists.

In order to allow more wholesalers to obtain greater profits, our factory continue to improve DTF printing technology and reduce costs. We provide a complete set of products and equipment for DTF printing.Here VISION factory share 9 Tips of DTF Printing for you. More information, please contact us anytime.

Another potential drawback of DTF is the thickness of the print. Because the ink is applied directly to the fabric, DTF prints can be thicker and heavier than traditional heat transfer methods. This may not be desirable for all applications, particularly if the garment is lightweight or if the design needs to be very subtle.

How does DTF printing work?

DTF printing process is a revolutionary technology that uses special water-based DTF pigmented inks to print onto polyethylene terephthalate (PET) film. Artwork will first be printed with a layer of colored ink before printing a second layer of white ink. Additionally, the printed artwork needs to be mirrored so that the application faces the correct direction when it is under the heat press, after which the printed image goes through an automatic powdering and curing machine.

Once printing and curing are complete, all that remains is to apply general finishing to the artwork. Using a heat press, transfer the artwork on the film to the fabric at approximately 170?for approximately 15 seconds before removing the film.

The end result will be just the desired artwork on the fabric. DTF can be applied to the same fabric products as thermal transfer paper. It is also worth mentioning that DTF technology is suitable for all kinds of fabrics, whether it is pure cotton or non-cotton fabrics, polyester, etc., as long as it is resistant to high temperature Products, basically can use DTF this product.

The DTF printing process generally includes: design>film printing>powder coating>curing>trimming>hot pressing>removing film>finishing.

Heat transfer printing

Heat transfer printing is a method of printing graphics or designs onto a surface using heat and pressure. This method is commonly used for printing on textiles, such as T-shirts, hats, and bags.

Here are some pros and cons of heat transfer printing:

Pros of Heat transfer printing

Versatility: Heat transfer printing can be used on a wide range of materials, including cotton, polyester, nylon, and even leather.

High-quality printing: Heat transfer printing produces high-quality, detailed images with bright, vivid colors.

Cost-effective: Heat transfer printing is a cost-effective method of printing small quantities of custom items. It is also relatively inexpensive to set up, making it a popular choice for small businesses and entrepreneurs.

Easy to use: Heat transfer printing is a simple process that requires minimal training. With a little practice, anyone can learn to use a heat press machine.

Durable: Heat transfer prints are generally more durable than other types of prints, such as screen printing or direct-to-garment printing. They are less likely to fade or crack over time, and they can withstand multiple washings.

Cons of Heat transfer printing

Limited color options: Heat transfer printing is best suited for simple designs with a limited number of colors. Complex designs with many colors may be more difficult to produce using this method.

Not suitable for all fabrics: Heat transfer printing is not recommended for certain fabrics, such as silk or other delicate fabrics that can be damaged by heat.

Not ideal for large quantities: Heat transfer printing is most cost-effective for small quantities of items. For large quantities, other printing methods may be more efficient and cost-effective.

Transfer lines: Heat transfer prints may leave visible transfer lines on the fabric, which can detract from the overall appearance of the item.

Limited design placement: Heat transfer prints are typically limited to flat areas of a garment or item, so designs cannot be placed on curved surfaces or seams.

What transfer paper do we provide?

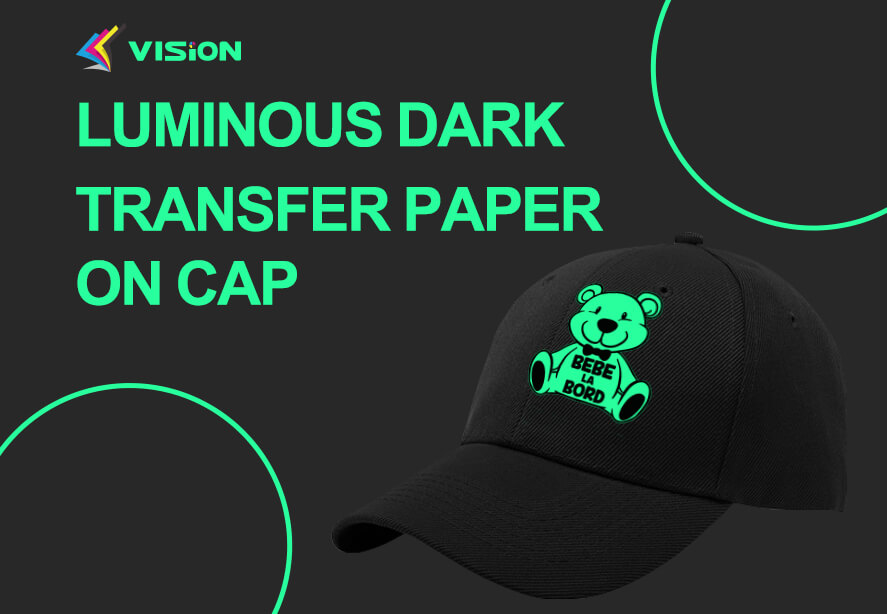

Heat transfer is one of the most common techniques used to customize fabric products. When it comes to heat transfer, there are many different papers in Shanghai Vision factory, like inkjet transfer paper, laser transfer paper, luminous paper, glitter paper and etc. It can absolutely meet your requirement. What you need is inkjet or laser printer and others. And if you need the hollow effect,we can also provide Self-Weeding (no-cut ) transfer paper for you,it is a hot seller in the market in recent years. About how to use Self-weeding Transfer Paper? This post will help you.

How does transfer paper work?

Different paper needs different transfer procedure, but these steps are very easy,just do as our requirement, you can get the best transfer effect.

After printing and cutting, you can get the transfer effect that you want.And different papers are used for different fabric, The transfer paper for digital printing process follows this workflow: Design > Print on Heat Transfer paper > Cut or not > Heat Press > Finish.

In conclusion

So, is DTF better than heat transfer? The answer, as with many things, is that it depends on your specific needs and preferences. If you are looking for a high-quality, detailed print that is durable and efficient to produce, DTF may be the better choice. However, if cost is a concern or if you need a very subtle or lightweight print, traditional heat transfer methods may be a better fit.

It’s also worth noting that there are other factors to consider beyond the printing method itself. For example, the type of garment or fabric you are printing on can have a significant impact on the final result. Some fabrics are more receptive to DTF than others, and some may require additional pre-treatment or post-treatment to ensure a good result. Similarly, the complexity of the design, the number of colors involved, and the size of the print can all affect which method is most appropriate.

Ultimately, the best way to determine which printing method is right for you is to experiment with both and see which produces the best results for your specific needs.