How to choose DTF film?

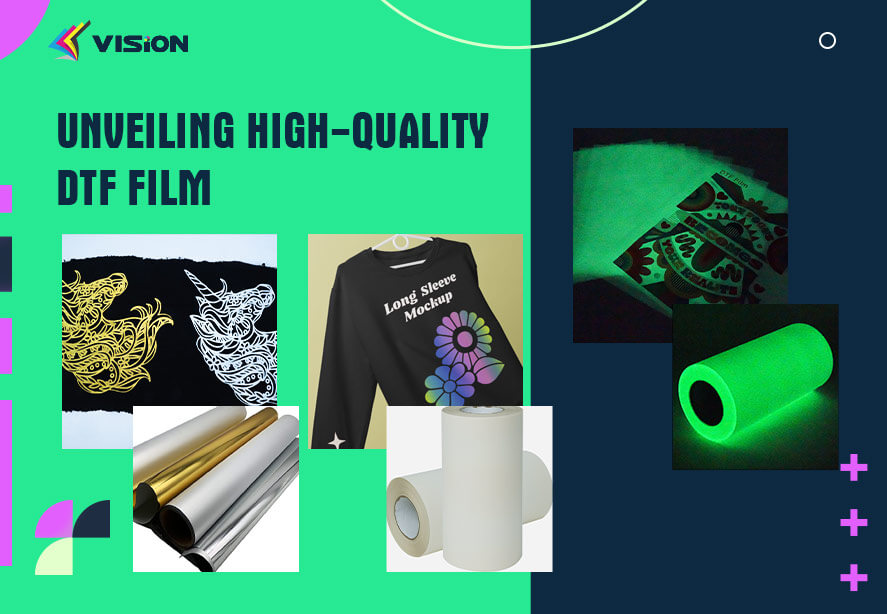

White ink direct jet heat transfer can be used for transferring on all fabrics, such as knitting, textile, nylon, non-woven fabric, Oxford cloth, etc. It solves the limitation of application carriers that require heat transfer consumables.Also,the cost is relatively low, and it is favored by more and more clothing customization companies. So how to choose good DTF film is very important.

Vision thermal transfer factory keeps up with the development of the market. In addition to production of the original heat transfer paper and heat transfer vinyl , we have been developed a new DTF coating line since 2018, and continuous research and development to improve the production process. In this article,we will introduce how to judge a DFT film is high quality or not, so that you can make a better choice.

1. Coating and surface of DTF film

As one of the thermal transfer products, the quality of the coating directly determines the effect of the printing. Of course, we can’t know the quality of the coating at once,also it depends on the equipment of the factory, so we must choose a big and trustable factory. At present, the DTF film produced by Vision factory is three-in-one. The three major requirements of ink absorption, release, and static removal are completed in one process, and the coating is very stable. we judge the quality of the coating is the performance of the film, whether there are black spots, whether there are scratches, whether there are creases, these will directly affect the printing.

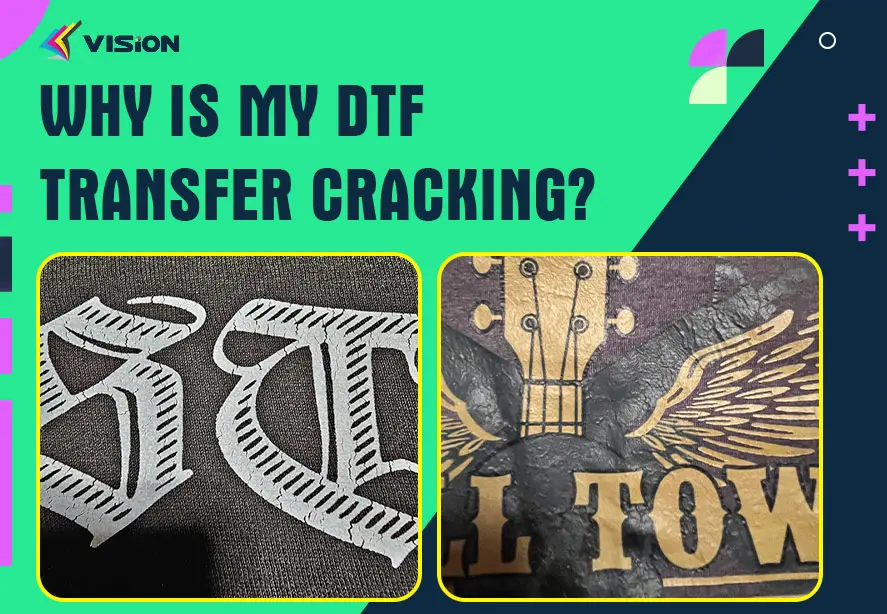

2. Printing effect

Printing is the first step of DTF film transfer. First of all, the basic requirements are whether it can be printed smoothly and can be completed without jamming or warping. Secondly, the quality of the film is mainly depended on the effect of printing, whether the ink will cause ink accumulation after printing. In the case of ink flow, we know that if the ink does not absorb well, the powder shaking will not be completed, and the pattern will not be used.Moreover, the color reproduction of the picture and the vividness of the color directly determine the color of the finished product.

3. Shaking powder

Shaking powder mainly depends on the quality of the ink and hot melt adhesive powder, but the quality of the film will also play a certain auxiliary role. The softness and hardness of the DTF film are very important, which is easy to operate.

4. Bake

Baking is a very important step in the thermal transfer process of D TF film. If you want to complete the perfect baking. It depends on three materials, film, hot melt adhesive powder, and ink. The heat resistance and drying time directly determines whether it can be completed smoothly. We will not go into details about the other two factors for the time being, we will have other articles detailing DFT hot melt adhesive powder and white ink printing ink. The quality of the film is mainly reflected in the heat resistance of the film. If the heat resistance of the film is not enough and the hot melt adhesive powder and ink are not fully dried and melted, the film will be broken, so it cannot be completed. So be sure to choose a film with relatively good heat resistance, but the heat resistance is not as long as possible.

5. Is DTF film hot peel or cold peel after transferring?

At present, most factories on the market produce cold-tear DTF films, and Vision can provide hot-tear DTF films; there is not much difference between cold-tear and hot-tear in the final appearance of the product; the main advantage of hot-tear is that it can save the time of the production process. The cold-tear DTF film needs to wait until the film is cold after the transfer and then peel off. But the hot-tear can be removed directly after the transfer, which saves a lot of time for mass production factories.

6. The storage of DTF film

Generally, the storage condition of DTF film is similar, it needs to be placed horizontally and protected from sunlight. However, the coating of good quality DTF film is more stable and not easily affected by the environment.

In general, DTF transfer has become an increasingly popular thermal transfer customized solution, and the quality on the market is uneven. I hope this article will help you judge the quality of DTF film. If you are interested in our DTF film, you can contact us. As a professional DTF film factory, VISION not only provide high-quality DTF film, but we can also provide a complete set of solutions for DTF, DTF printer, DTF ink, DTF powder, shaking powder, baking, heat transfer machine, etc. For more information, you can view our website or follow our social platform, we will update mor information for you.

Whatsapp: +86-18001836806

E-mail: info@visionsub.com

Web: https://www.visionsub.com/

Facebook: https://www.facebook.com/itransferpaper/

Youtube: https://www.youtube.com/c/VISIONsublimationpaper/videos