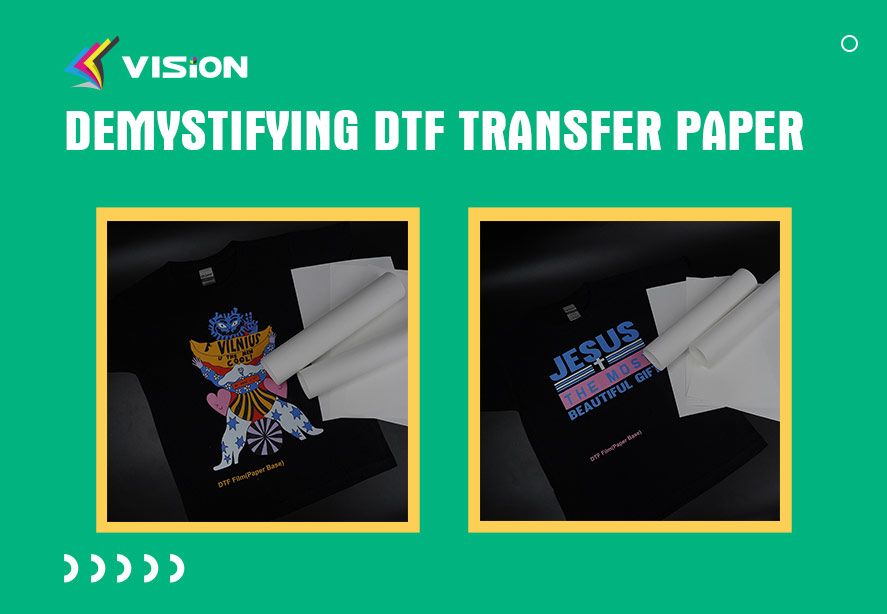

DTF paper is a popular printing method used in the garment industry. It stands for “Direct to Film,” referring to the process of printing designs directly onto a special film that can be transferred onto various fabrics. In this article, we will explore what DTF transfer paper is, how it works, its advantages and disadvantages, and its applications in the garment printing industry.

What is DTF Transfer Paper?

DTF transfer paper is a type of heat transfer paper specifically designed for the DTF printing process. DTF printing is a relatively new technology that has gained attention for its ability to produce high-quality and durable prints on a wide range of fabrics, including cotton, polyester, and blends. Unlike traditional heat transfer methods that use vinyl or sublimation, DTF printing involves printing the design onto a special film using a DTF printer and then transferring it onto the fabric using heat and pressure.

Related:

The Ultimate Guide to DTF Printing

How Does DTF Transfer Paper Work?

The DTF printing process involves several steps:

Design Creation: The first step in the DTF printing process is creating or selecting a design that you want to transfer onto the fabric. This can be done using graphic design software.

Printing onto DTF Paper: Once the design is ready, it is printed onto a special DTF paper using a DTF printer. The printer uses a combination of ink and adhesive powder to create the design on the paper.

Paper Preparation: After printing, the DTF paper needs to go through a curing process to ensure that the ink and adhesive powder are properly bonded. This can be done using a heat press or a curing machine.

Transfer onto Fabric: Once the paper is ready, it is placed on top of the fabric, and heat and pressure are applied using a heat press. The heat and pressure activate the adhesive powder on the paper, causing it to bond with the fabric fibers, resulting in a permanent transfer of the design.

Peeling and Finishing: After the transfer is complete, the paper is peeled off, revealing the printed design on the fabric. Some finishing steps may be required, such as curing the print again or applying a protective coating for added durability.

How To Use New DTF Paper Step by Step?

Advantages of DTF Transfer Paper

DTF transfer paper offers several advantages over other printing methods:

1.Environmentally Friendly Material

DTF transfer paper is crafted with environmental sustainability in mind. The material used in its production aligns with eco-friendly standards, making it a responsible choice for conscious printing businesses.

2.Compatibility with DTF Inks and DTF Power

One of the key strengths of DTF transfer paper lies in its seamless compatibility with DTF inks and DTF Power. This compatibility ensures optimal printing results, enhancing the efficiency of the overall printing process.

3. High Stretchability and Soft Hand Feel

DTF transfer paper offers more than just environmental benefits; it also provides high stretchability and a soft hand feel. This translates to comfortable and flexible T-shirts that not only look good but feel great to wear.

4. Durable with Great Washabilit

Durability is a hallmark of DTF transfer paper. The prints produced using this technology exhibit remarkable resilience, standing the test of time and numerous wash cycles. This longevity adds significant value to the printed T-shirts.

5. Vivid Colors After Transfer

Achieving vibrant colors is a priority in T-shirt printing, and DTF transfer paper excels in this aspect. The technology ensures that the transferred colors remain vivid and eye-catching, enhancing the overall visual appeal of the printed designs.

Vivid Colors After Transfer

6.Cost-Effective

Compared to other printing methods like sublimation or screen printing, DTF printing can be more cost-effective, especially for small to medium-sized production runs.

7.No Color Limitations

Unlike traditional screen printing, DTF printing does not have any color limitations. It can reproduce virtually any color or shade accurately.

Disadvantages of DTF Transfer Paper

While DTF transfer paper offers many advantages, there are some limitations and challenges to consider:

Learning Curve: DTF printing is a relatively new technology, and there can be a learning curve involved in mastering the process. It may require experimentation and practice to achieve optimal results.

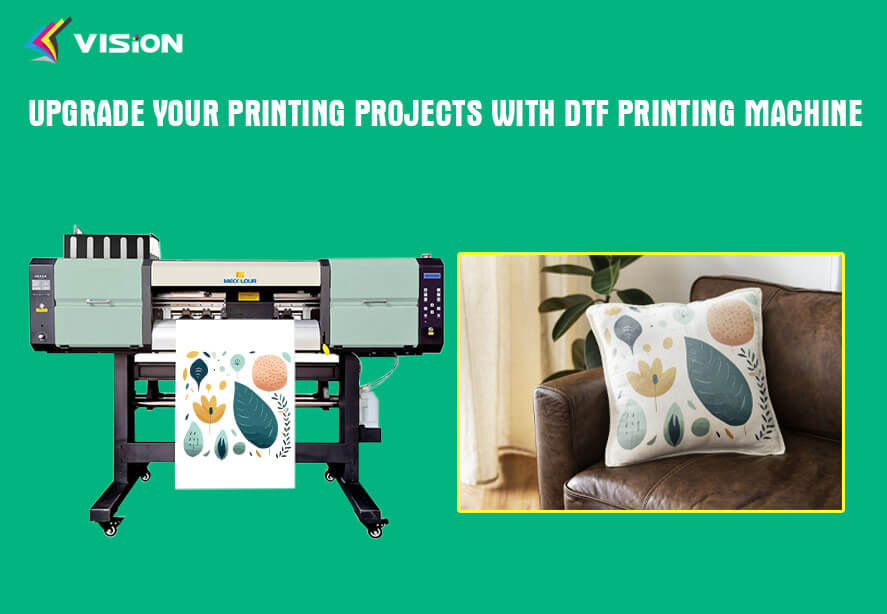

Equipment and Supplies: DTF printing requires specific equipment, including a DTF printer, heat press, and DTF paper. Additionally, the specialized DTF ink and adhesive powder need to be used, which may require a separate investment.

Pre-Treatment: Some fabrics may require pre-treatment, such as applying a bonding agent or coating, to ensure proper adhesion of the DTF transfer. This additional step adds complexity to the process.

Limited Availability: DTF transfer paper and related supplies may not be as widely available as other printing materials, making it more challenging to source them.

Environmental Considerations: DTF printing involves the use of ink and adhesive powder, which may have environmental implications. Proper disposal and handling of these materials are important to minimize any negative impact.

Applications of DTF Transfer Paper

DTF transfer paper finds applications in various areas of the garment printing industry, including:

Apparel Manufacturing: DTF printing is commonly used for producing custom t-shirts, hoodies, and other apparel items. It allows for on-demand printing and customization, making it suitable for small to medium-sized production runs.

Fashion and Design: DTF printing enables designers to bring their intricate and colorful designs to life. It can be used to create unique patterns, graphics, and textures on garments, adding value and uniqueness to fashion collections.

Promotional Products: DTF printing can be used to create promotional items such as personalized bags, caps, and accessories. It allows for high-quality prints with vibrant colors, making promotional productsstand out and leave a lasting impression.

DTF Paper on hoodies and tote bags

Sports and Team Apparel: DTF printing is commonly used for producing sports jerseys, team uniforms, and other athletic apparel. It allows for customization with player names, numbers, and team logos, providing a professional and personalized look.

Merchandise and Branding: DTF printing is a popular choice for creating branded merchandise, such as t-shirts, hoodies, and tote bags. It allows businesses and organizations to showcase their logos and designs on high-quality products, helping to build brand awareness and loyalty.

Making the Switch to Sustainable T-Shirt Printing

As the demand for eco-friendly solutions grows, DTF transfer paper emerges as a sustainable choice for T-shirt printing businesses. Making the switch not only contributes to environmental conservation but also opens doors to enhanced print quality and customer satisfaction. Whether it’s for apparel manufacturing, fashion design, promotional products, or branding purposes, DTF transfer paper provides a reliable and efficient solution for creating eye-catching and long-lasting prints.

Related:

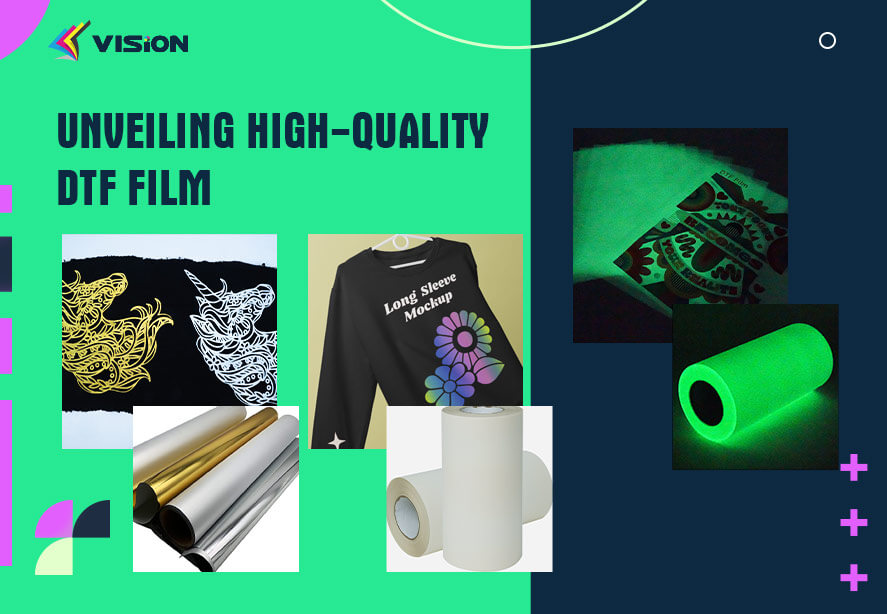

2023 New:DTF Film with Iridescent Effect for T-Shirt Printing

DTF Film Roll: Creating Diamond Effect T-Shirt Prints