Sublimation printing has revolutionized the world of digital printing, allowing for vibrant and long-lasting prints on a wide range of materials. At the heart of this printing process lies the sublimation paper roll, a crucial component that enables the transfer of images onto various substrates. In this comprehensive guide, we will explore the benefits, techniques, troubleshooting, and future innovations associated with sublimation paper roll. Whether you’re a professional printer or an enthusiastic DIYer, understanding the magic of sublimation paper roll will elevate your printing projects to new heights.

Understanding Sublimation Paper Roll

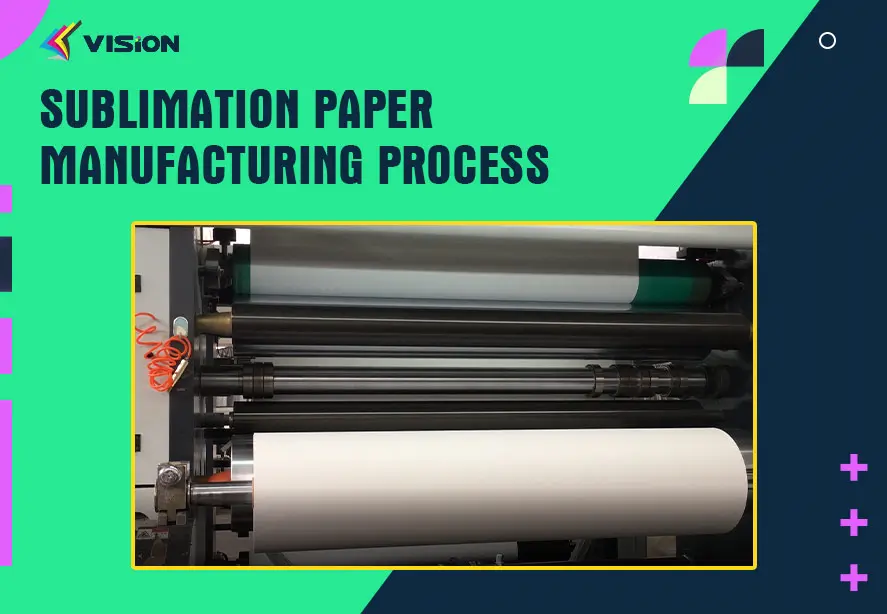

Sublimation paper roll is a specially coated paper that acts as a carrier for sublimation ink. It plays a crucial role in the sublimation printing process by absorbing the ink and releasing it onto the desired material. The coating on the paper enables the ink to transform from a solid to a gas state when heat is applied, allowing it to permeate the fibers of the substrate and create vibrant, high-resolution prints.

The Benefits of Using Sublimation Paper Roll in Your Printing Projects

Sublimation paper roll offers several advantages over other printing methods. Firstly, it allows for photo-realistic prints with exceptional color vibrancy, sharpness, and durability. The sublimation process ensures that the ink becomes a part of the material rather than sitting on the surface, resulting in prints that are resistant to fading, cracking, or peeling.

Moreover, sublimation paper roll provides versatility in terms of the substrates it can be used with. From textiles and garments to ceramics, metals, and plastics, the sublimation process can be applied to a wide array of materials, making it suitable for various applications such as apparel, signage, home decor, promotional items, and more.

Step-by-Step Tutorial: How to Use Sublimation Paper Roll for Remarkable Prints

Step 1: Designing Your Artwork

Begin by creating or selecting the artwork you wish to print. Ensure that it is of high resolution and suitable for sublimation printing.

Step 2: Preparing Your Substrate

Prepare your substrate by cleaning and pre-pressing it to remove any moisture or wrinkles. This step is crucial to ensure optimal transfer of the ink.

Step 3: Printing Your Design

Load the sublimation paper roll into your printer and set the appropriate settings for your artwork. Print your design onto the paper, making sure to mirror the image if necessary.

Step 4: Preparing for Transfer

Place the printed sublimation paper roll on top of your substrate, ensuring that it is positioned correctly. Use heat-resistant tape to secure the paper in place, preventing any movement during the transfer process.

Step 5: Heat Press Transfer

Set your heat press machine to the recommended temperature and time settings for the specific sublimation paper roll and substrate you are using. Apply even pressure and heat to the paper and substrate, allowing the ink to transfer and penetrate the material.

Step 6: Removing the Paper and Inspecting the Print

Carefully remove the sublimation paper from the substrate, peeling it back in a smooth and controlled manner. Inspect the print for any inconsistencies or areas that may require touch-ups.

Step 7: Finalizing the Print

If needed, perform any necessary post-processing steps such as trimming, hemming, or curing the print. Your stunning sublimation print is now ready to be showcased or incorporated into your desired project.

This video is 60gsm sublimation printing by VISION

Choosing the Right Sublimation Paper Roll: Factors to Consider

When selecting a sublimation paper roll, several factors come into play. These include the type of printer you have, the specific materials you intend to print on, the desired image quality, and the budget. It’s important to choose a sublimation paper roll that is compatible with your printer’s ink type and is specifically designed for the materials you plan to work with. Consider the weight, size, and finish of the paper roll, as they can affect the final print quality and overall user experience.

Exploring Different Sublimation Paper Roll Options: Which One is Right for You?

The market offers a variety of sublimation paper roll options to cater to different printing requirements. Some key considerations when exploring your options include:

Paper Weight: Lighter weight papers are suitable for softer materials, while heavier weight papers work well for rigid substrates. (The weights VISION offers are: 45g,60g,70g,80g,90g,100g,120g, if you want to know more details,please contact us.)

Size: Choose a paper roll size that matches your printer’s specifications and the dimensions of your printing projects.

Finish: Glossy finishes provide vibrant colors and sharp details, while matte finishes offer a more subdued and elegant look.

Drying Time: Consider the drying time required for the paper roll you choose, as it can impact your workflow and productivity.

Troubleshooting Common Issues When Working with Sublimation Paper Roll

Despite its many advantages, sublimation printing can sometimes present challenges. Here are some common issues you may encounter when working with sublimation paper roll and their possible solutions:

Blurred Prints: Ensure that your artwork is of high resolution and that your printer is set to the appropriate settings for optimal print quality.

Color Inconsistencies: Calibrate your printer regularly and use color profiles specific to your sublimation paper roll and substrate.

Uneven Transfers: Check that your heat press machine is applying even pressure and heat across the entire surface of the print.

Paper Jams: Ensure that the sublimation paper roll is properly aligned and loaded into your printer to prevent paper jams.

Ink Bleeding: Avoid excessive ink saturation by following recommended ink usage guidelines and adjusting print settings if necessary.

Best Practices for Handling, Storing, and Preserving Sublimation Paper Roll

To ensure the longevity and optimal performance of your sublimation paper roll, it’s essential to follow best practices for handling, storing, and preserving:

Handle the paper roll with clean and dry hands to prevent moisture or oil transfer.

Store the paper roll in a cool and dry environment, away from direct sunlight or humidity.

Keep the roll upright to avoid creasing or damage to the edges.

Use the paper roll within its recommended shelf life to maintain optimal print quality.

Tips and Techniques for Achieving Perfect Results with Sublimation Paper Roll

To take your sublimation printing to the next level and achieve perfect results, consider the following tips and techniques:

Perform test prints and color swatches to fine-tune your settings and achieve accurate color representation.

Experiment with different heat press pressure and temperature settings to find the optimal combination for each material and print.

Use high-quality, original sublimation inks that are compatible with your printer and sublimation paper roll.

Explore various finishing techniques such as lamination, coating, or pressing to enhance the durability and appearance of your prints.

The Future of Sublimation Printing: Innovations and Trends in Paper Roll Technology

As technology continues to advance, so does the world of sublimation printing. Innovations in paper roll technology are expected to bring about exciting possibilities for the future. Some emerging trends include:

Faster Drying Times: New paper roll formulations that enable faster drying of sublimation inks, increasing productivity and reducing production time.

Improved Color Gamut: Enhanced ink formulations and specialized coatings on paper rolls that allow for a wider range of colors and more accurate color reproduction.

Eco-Friendly Options: The development of eco-friendly sublimation paper that minimize environmental impact by using sustainable materials and reducing waste.

Advanced Coating Technologies: Innovations in coating techniques that offer improved ink absorption, resulting in even higher image resolution and clarity.

With these advancements on the horizon, sublimation printing is set to become even more versatile, efficient, and environmentally friendly.

Sublimation paper plays a pivotal role in achieving stunning, vibrant, and long-lasting prints. Its ability to transfer images onto various substrates with exceptional color accuracy and durability makes it a preferred choice for professionals and DIY enthusiasts alike.

FAQ

No, sublimation paper roll requires a printer that is specifically designed for sublimation printing. These printers are equipped with specialized inks and heating elements to facilitate the sublimation process.

Sublimation paper roll is designed for single-use. Reusing the paper can result in reduced print quality and inconsistent transfer of the ink.

While sublimation paper roll is compatible with a wide range of materials, it is important to consider the heat resistance and porosity of the substrate. Some materials may require pre-treatment or may not be suitable for sublimation printing.

The drying time of sublimation ink can vary depending on factors such as ink formulation, paper coating, and environmental conditions. Generally, it takes a few minutes for the ink to dry completely.

Sublimation paper roll is primarily designed for use on light-colored or white substrates. The sublimation process relies on the ink's ability to penetrate the material and become a part of it, which may not be possible on dark-colored fabrics.