Sublimation printing has become a popular method for creating vibrant and long-lasting designs on various surfaces. Traditionally used on polyester fabrics, advancements in technology have made it possible to explore sublimation on cotton, a preferred fabric in the fashion industry. In this article, we will delve into the world of sublimation vinyl on cotton.

Suitable Materials for Sublimation

While sublimation works exceptionally well on polyester, it has its unique challenges when applied to cotton. However, with the right sublimation vinyl and preparation, stunning results can be achieved.

The Popularity of Cotton in the Printing Industry

Cotton as a Preferred Fabric for Clothing

Cotton has been a go-to fabric for clothing due to its comfort, breathability, and versatility. By enabling sublimation on cotton, designers can offer a wider range of customized apparel options to their customers.

Challenges of Sublimation on Cotton

Sublimating on cotton can present challenges such as color vibrancy, wash durability, and image distortion. However, with proper techniques and high-quality sublimation vinyl, these challenges can be overcome.

Advantages of Sublimation Printing on Cotton

The advantages of sublimation on cotton include the soft and natural feel of the fabric, making it an attractive option for creating unique and personalized designs.

Preparing for Sublimation on Cotton

Pre-Treating Cotton Fabrics for Optimal Results

To ensure the best results, pre-treating cotton fabrics is essential. Pre-treatment helps the fabric better absorb the sublimation ink, resulting in sharper and more vibrant designs.

Selecting the Right Sublimation Vinyl for Cotton

When it comes to sublimation printing on cotton fabrics, selecting the right sublimation vinyl is a critical factor in achieving vibrant and durable designs. High-quality vinyl allows for better color retention and ensures the design remains intact after washing. VISION is a leading manufacturer of high-quality sublimation vinyl, offering a wide range of options to cater to various printing needs.

Factors to Consider When Selecting Sublimation Vinyl for Cotton

1. Compatibility with Cotton Fabrics

When looking for sublimation vinyl, ensure that it is specifically designed for use on cotton fabrics. While sublimation is traditionally used on polyester, specialized vinyl made for cotton will ensure better ink absorption and longevity of the design.

2. Quality and Durability

VISION takes pride in offering high-quality sublimation vinyl that is durable and fade-resistant. Inferior vinyl may lead to unsatisfactory results and shorter print lifespans. Opting for reliable and long-lasting materials will ensure customer satisfaction and repeat business.

3. Ease of Application

Choose sublimation vinyl that is easy to work with and applies smoothly to the cotton fabric. VISION’s vinyl is user-friendly, allowing for seamless application and minimizing the risk of errors during the printing process.

4. Eco-Friendly Options

For environmentally-conscious businesses, VISION offers eco-friendly sublimation vinyl that minimizes the environmental impact of the printing process. These options are ideal for those aiming to adopt sustainable practices.

5. Compatibility with Printing Equipment

Ensure that the chosen sublimation vinyl is compatible with your printer and heat press machine. VISION provides vinyl that works seamlessly with various printing equipment, ensuring a hassle-free printing experience.

VISION: Your Trusted Partner for Sublimation Vinyl

With years of experience in the digital printing industry, VISION has established itself as a reliable supplier of high-quality sublimation vinyl. Their commitment to excellence and customer satisfaction has made them the first choice of wholesalers, retailers, agents all over the world.

How to use VISION sublimation vinyl?

Necessary Equipment and Tools

Having the right equipment and tools, including a printer, Sublimation ink, Cutting plotter, heat press machine, and suitable software, is vital for a smooth printing process.

Step-by-Step Guide to Sublimation on Cotton

Step 1: Preparing Your Design

Begin by creating or selecting a design using graphic design software. Ensure the design is high-resolution and suitable for sublimation.

Step 2: Printing Your Design on Sublimation Paper

Print the design on sublimation paper using a printer. Be mindful of the paper size and color profile settings for accurate printing.

Print Mode: Mirror Print, High Quality Glossy Paper, Standard Print Quality.

Note: Record the size settings of the printed pattern.

Step 3: Cut excess parts

Re-upload the pattern to the software of the cutting plotter (Note: The size of the pattern needs to be the same as the printed pattern), then click the offset and set the distance of the outline to 0.1mm and cut out the pattern (if the pattern is complex and small, the offset can be appropriately increased; if it is simple and the offset can be appropriately reduced).

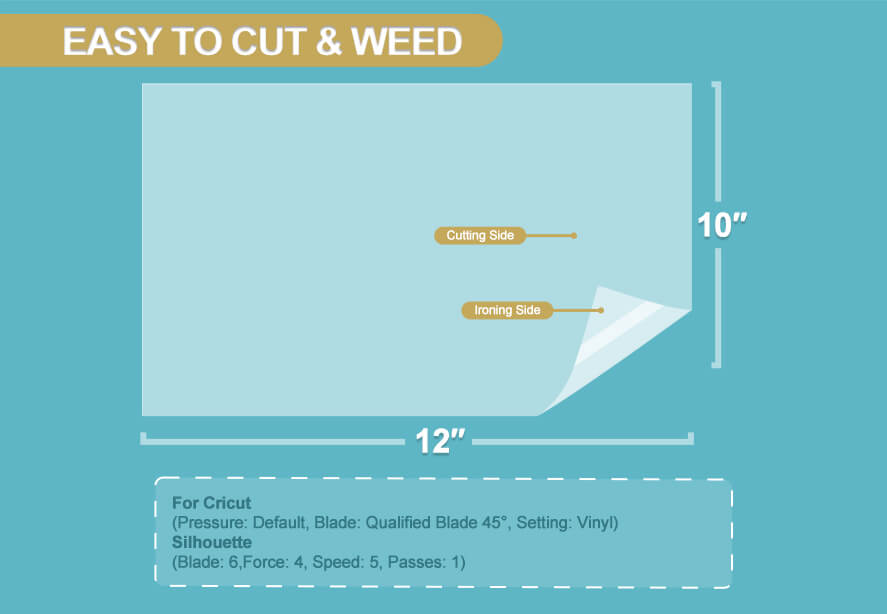

Take out the sublimation vinyl, cut out the outline edge of the pattern by the cutting plotter, and then weed the extra parts. (Note: Cutting Mode:Mirror).

Step 4:Transfer the pattern

Set heat press parameters: Temperature: 185?, Pressure: medium.

Put the sublimation HTV vinyl face up on the fabric, iron at 185? for 5 seconds, and remove the base film of the sublimation vinyl (Cold Peel).

Put the printed sublimation paper on the sublimation vinyl,Align and fix the pattern.Iron with a heat press machine at 185°C for 40 seconds, peel off the sublimation paper(cold peel).

Step 5: Finishing Touches and Quality Control

Once the heat press process is complete, carefully remove the sublimation vinyl. Inspect the fabric for any imperfections and make necessary adjustments for future prints.

How to use sublimation HTV vinyl on cotton fabric?

Troubleshooting Common Sublimation Issues on Cotton

Fading and Color Blending Problems

To prevent fading and color blending issues, ensure the fabric is properly pre-treated and that high-quality sublimation vinyl is used.

Uneven Transfer and Patchy Results

Uneven transfer and patchy results can be minimized by using even pressure and heat during the heat press process.

Image Distortion and Blurriness

Image distortion and blurriness can be avoided by using high-resolution designs and ensuring the fabric remains flat during pressing.

You can also read this article 6 Tips: Using VISION Sublimation vinyl on light cotton to learn more about our product.

Tips and Tricks for Better Sublimation Results

Achieving Vibrant Colors on Cotton

To achieve vibrant colors on cotton, use sublimation vinyl specifically designed for cotton fabrics and follow the manufacturer’s guidelines.

Maximizing Wash Durability

To enhance wash durability, consider using high-quality sublimation vinyl and following proper washing instructions.

Layering Techniques for Multi-Color Designs

Layering sublimation vinyl allows for intricate multi-color designs, adding depth and dimension to the final product.

Sublimation vinyl on cotton opens up a world of creative possibilities in the printing industry. Do you want to make your business more profitable? welcome to inquire about our new products and new technologies, contact us for free sample testing!