Sticky sublimation paper is a key component in the sublimation printing process as it plays an important role in transferring vivid and long-lasting designs to a variety of substrates. For any factory that specializes in heat transfer printing, producing the high quality sticky sublimation paper is crucial. For users and businessmen engaged in digital printing, it is more important to choose a suitable sublimation paper factory to meet the needs of the market.

VISION, as a professional digital printing factory, will delve into how to choose the right sticky sublimation paper for your printing needs. Below, let’s explore the factors to consider when choosing sticky sublimation paper and ensure your prints come out perfect every time.

What is Sticky Sublimation Paper?

Sticky sublimation paper, also known as tacky sublimation paper, is designed with a specialized coating that adheres to the fabric during the heat transfer process. This adhesive layer helps to prevent any movement or shifting of the paper during pressing, ensuring precise and sharp prints. It’s particularly useful when printing on slippery or stretchy fabrics.

Consider Your Printing Needs

The first step in choosing the right sticky sublimation paper is to consider your specific printing needs. Take into account the type of substrate you’ll be working with, whether it’s fabrics, ceramics, metals, or other materials. Different sticky sublimation papers are designed for specific substrates, so ensure that the paper you choose is compatible with your intended materials.

Quality of the Paper

The quality of the sticky sublimation paper is crucial for achieving excellent print results. Look for a paper that is specifically manufactured for sublimation printing, as these papers are designed to handle high ink loads and deliver vibrant colors. The paper should have a smooth surface to ensure proper ink absorption and prevent any ink bleeding or smudging.

Coating quality of the paper

When it comes to printing, the quality of the coating on the paper plays a crucial role in achieving optimal image sharpness, color vibrancy, and overall print quality. Coatings are applied to the surface of the paper to enhance its properties and improve the reproduction of images.

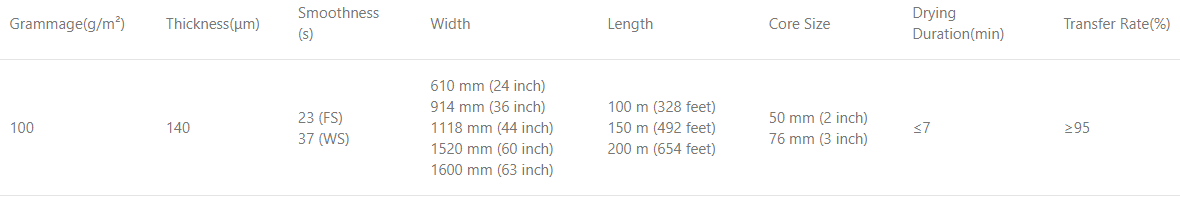

Size and Thickness

Consider the size and thickness of the sticky sublimation paper based on your printing requirements. Determine the maximum width that your printer can handle, as sticky sublimation papers come in various widths. Additionally, the thickness of the paper can affect the printing process and the durability of the final print. Thicker papers generally offer better ink absorption and can withstand multiple washes without losing color vibrancy.

The different widths of VISION sticky sublimation paper

Transfer Rate and Drying Time

The transfer rate of the sticky sublimation paper refers to the speed at which the ink is transferred from the paper to the substrate during the heat press process. Look for a paper with a high transfer rate to achieve quick and efficient transfers, saving you time and increasing productivity. Additionally, consider the drying time of the paper after printing. Faster drying times can be beneficial, especially when working on large printing projects.

Compatibility with Printer and Ink

Ensure that the sticky sublimation paper you choose is compatible with your printer and the sublimation ink you’ll be using. Check the specifications provided by the paper manufacturer to verify compatibility. Using the correct combination of paper, printer, and ink will ensure optimal print results and prevent any damage to your equipment.

User-Friendliness

Consider the user-friendliness of the sticky sublimation paper, especially if you’re new to sublimation printing. Look for papers that are easy to handle, load, and align on the heat press or printer. Some papers come with gridlines or other alignment aids to assist in precise positioning of the designs.

Three kinds of sticky sublimation paper from Vision Company

Cost and Value

Finally, consider the cost and value of the sticky sublimation paper. While it’s important to stay within your budget, remember that the cheapest option may not always provide the best results. Look for a balance between cost and value, considering factors such as print quality, durability, and ease of use. Investing in a higher-quality paper may result in better prints and reduce wastage in the long run.

In the complex world of sublimation printing, Choosing the right sticky sublimation paper is essential to achieve outstanding print results in your sublimation printing projects. Consider factors such as your printing needs, paper quality, size and thickness, transfer rate, compatibility, user-friendliness, and cost. By selecting the appropriate sticky sublimation paper, you’ll be on your way to creating vibrant and professional prints on various substrates. If you require further assistance or enquiries, our factory team will be happy to support you.

Related:

What Factors affect the stickiness of sublimation paper?

Introduction about sticky sublimation paper

What is Sticky Sublimation Paper and How to choose it?