What is DTF printing?

DTF(Direct to Film) is an alternative printing process for DTG. DTF use a specific type of water-based ink to print the film for transfer, dry, apply powdery glue on the back, and then heat cure for storage or use immediately. That is to say,dtf printing is to print on the film and directly transfer to the fabric.

It don’t need to use pretreatment, powdered glue will complete the job for you. It is one of the advantages of DTF printing.The dtf ink is transferred to the garment within 15 seconds after heat pressing. This transfer method solves the problem that traditional DTG printing is difficult to print on non-cotton fabrics such as polyester.Almost any fabric can be transferred, whether it is polyester, cotton, silk or man-made fibers, such as rayon or terry cloth,the DTF printing process will definitely prints them the perfect pattern.

DTF Printing Step-by-step Tutorial

What do you need for DTF printing?

You needn’t make a lot of investment for DTF printing. Whether you are currently engaged in one of the above-mentioned textile digital printing processes and want to switch to DTF printing as a business extension, or those who want to get involved in digital printing from DTF, they must have the following conditions:

1.Direct to film printers

Most of these printers are basic 6-color ink cartridge printers, such as Epson L800, L805, L1800, etc. The reason for choosing this series of printers is that these printers support 6 colors. This provides convenience for operation, because CMYK DTF ink can enter standard CMYK ink tanks, and the printer’s LC and LM ink tanks can be filled with white DTF ink. To prevent “lining” from appearing on the white layer printed on the DTF film, the roller used to slide the page was also removed.

2.Film

PET film is used in DTF printing process. These films are different from those used in screen printing. They have a thickness of approximately 0.75 mm and better transmission characteristics. In market, these are often referred to as DTF transfer films. DTF film is available in the form of sheet paper (for small-scale use) and roll paper (for large-scale commercial use). Another classification of PET film is based on the type of peeling after transfer. DTF film is divided into hot peeling film or cold peeling film.

3. Software

Software is an important part of the DTF printing process. The printing characteristics, color performance of ink and the final printing effect on the fabric after transfer are greatly affected by the software. For DTF, a special RIP software is needed,it can handle CMYK and white. Color configuration, ink volume, ink drop size and other factors that help optimize printing results are all controlled by DTF printing software.

4. Hot melt adhesive powder

DTF printing powder is white. It is used as a binding material to bind the colored pigments in the printing to the fibers. DTF hot-melt adhesive powder is measured in micrometers and has different grades. The appropriate level should be selected according to the requirements.

5.DTF printing ink

These are specially designed pigment inks, available in cyan, magenta, yellow, black and white. White ink is a special component that can lay the white foundation of the printed matter on the film and print a colored design on it.

6. Automatic powder vibrator

Automatic powder shakers are used in commercial DTF settings to evenly apply powder and remove excess powder.

7. Curing oven

The curing furnace is basically a small industrial furnace for melting the hot-melt powder coated on the transfer film. A heat press can also be used to perform this operation, but it should be used in non-contact mode.

8. Heat press

The heat press is mainly used to transfer the image printed on the film to the fabric. It can also be used to heat hot melt powder on DTF film.

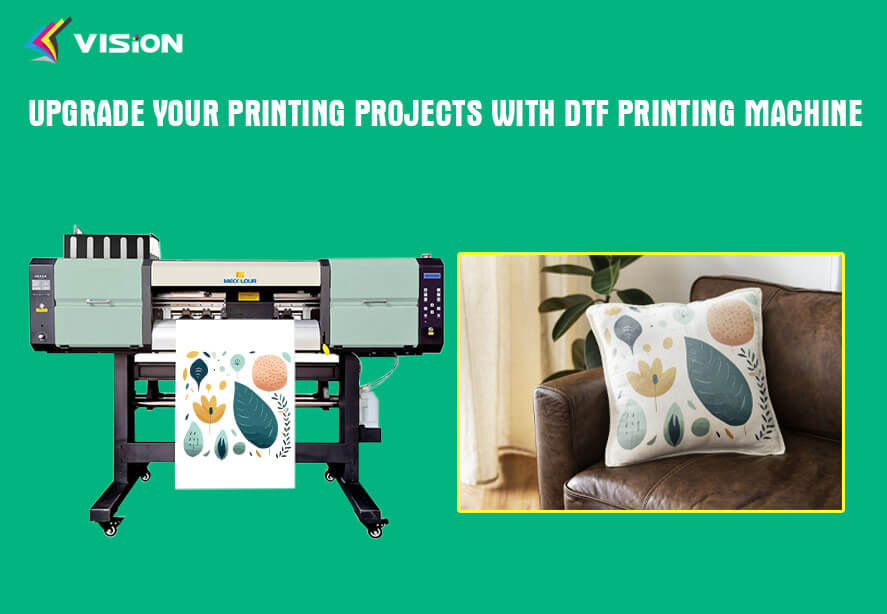

VISION has been committed to the research and development of new dtf printing technology for many years, and DTF is a supplement that cannot be ignored in the apparel industry.DTF printing don’t need pre-processing.Because special inks and adhesives enhance durability, DTF printing is ideal for printing clothes, gym clothes and cycling clothes,etc. Because of the use of water-based ink, it will not crack like screen printing, and it feels very soft.

Of course, vision is not only a dtf printing factory, we specialize in the production of digital transfer products, such as heat transfer paper, sublimation paper, heat transfer vinyl and other digital media products. For more information, please follow our official website or social platforms. If necessary, Feel free to contact us.

Whatsapp: +86-18001836806

E-mail: info@visionsub.com

Web: https://www.visionsub.com/

Facebook: https://www.facebook.com/itransferpaper/

Youtube: https://www.youtube.com/c/VISIONsublimationpaper/videos

Linkedin: https://www.linkedin.com/company/76525487/admin/