Since thermal transfer technology has developed very well in the current market, especially in the T-shirt thermal transfer industry, the development of heat transfer paper manufacturers in the market is still very good, as long as there is demand in the market , thermal transfer paper manufacturers can be well developed.

As a heat transfer paper wholesaler, it is very important to choose a very reliable manufacturer. What aspects need to be considered when choosing a heat transfer paper factory?

When choosing a heat transfer paper factory, you should pay attention to the professionalism, production efficiency and scale of the manufacturer’s production. The heat transfer paper produced by reliable transfer paper manufacturers has good quality and good transfer effect, which can meet the needs of customers for high-quality paper. The professionalism of the thermal transfer paper manufacturer will affect the quality of the paper, and even the quality and value of the subsequent products, so before purchasing thermal transfer paper, you must choose a reliable manufacturer.

In order to ensure that the customer’s demand for transfer paper can be met in the later stage, it is necessary to understand its scale and production efficiency in advance when choosing a thermal transfer paper manufacturer. It is estimated that the manufacturer’s supply speed can keep up with the company’s demand for transfer paper. So the production efficiency is an aspect that needs to be paid attention to when choosing a manufacturer.

The sales and technical level of the transfer paper factory are also critical. Manufacturers with good sales indicate that the quality of the products, and they have a professional technical team.The quality of raw materials selected by such manufacturers is relatively good. Because if the choice of raw materials is not good,the final transfer effect is still very different.Besides, as long as the manufacturer develops well, the overall value will be higher.

How to use thermal transfer paper?

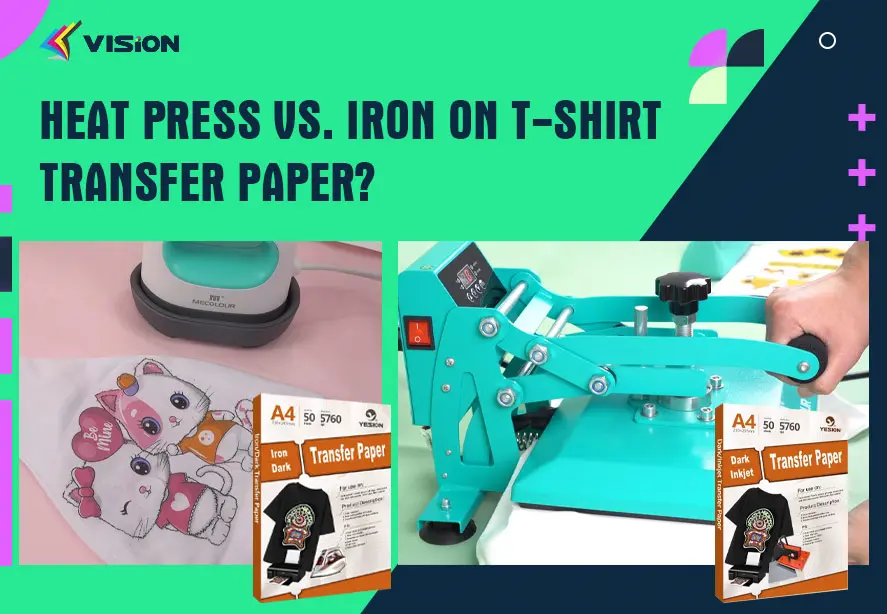

Generally speaking, thermal transfer printing is mainly divided into three processes. First, we need to process the pictures through the computer, which is commonly known as ps. After processing the picture, we can print the picture onto the heat transfer paper with a inkjet printer or laser printer. After that, we use a special heat press machine to transfer our pictures on the fabric under a certain pressure and temperature.It takes a certain time to fully complete the transfer.

It seems relatively simple, the actual operation is not simple. We need to adjust the appropriate time and the corresponding temperature and pressure during the transfer process. Only when these conditions are well controlled can we finally ensure that the thermal transfer is successful.

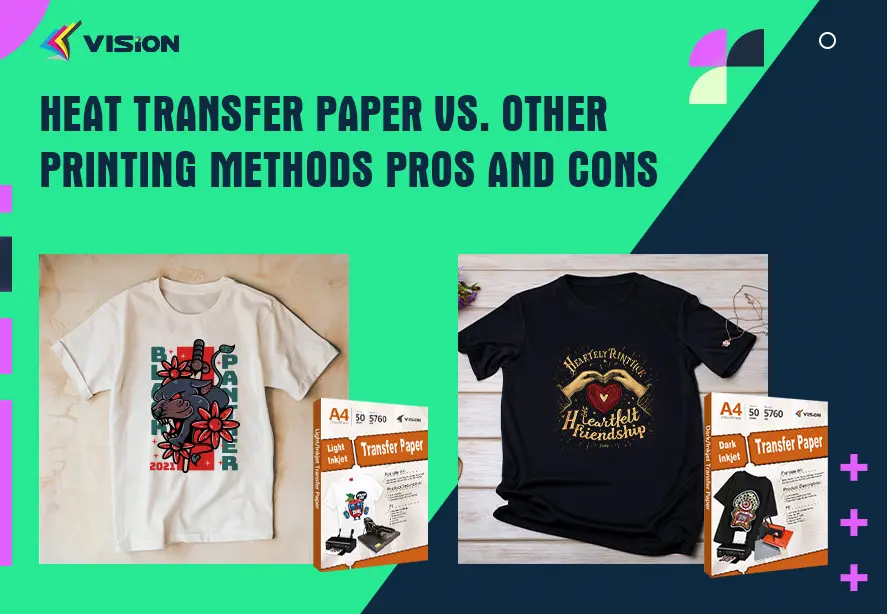

Thermal transfer paper is also divided into many types, we need to use suitable paper for thermal transfer. The thermal transfer paper provided by VISION includes inkjet transfer paper and laser transfer paper. If you need it for home DIY, you can choose our iron on transfer paper. For specific product features and specific instructions for use, please refer to our official website or watch the video. If necessary, please feel free to contact us!