Blog

Heat Transfer Vinyl vs Inkjet Transfer Paper: Which Is Best for You

When it comes to custom apparel printing, two of the most widely used methods are heat transfer vinyl and inkjet transfer paper. Each technique offers distinct advantages, limitations, and ideal use cases. We consistently see confusion among beginners and even experienced creators when deciding between these two solutions.

This in-depth comparison of heat transfer vinyl vs inkjet transfer paper is designed to help you make a confident, informed decision—whether you are creating DIY T-shirts at home or running a growing apparel customization business. Below, we present a precise, practical breakdown focused on performance, durability, cost efficiency, design flexibility, and production workflow.

What Is Heat Transfer Vinyl

Heat transfer vinyl is a specialty vinyl material with a heat-activated adhesive backing. Designs are cut from solid-colored vinyl sheets and then pressed onto fabric using heat and pressure.

Key Characteristics of Heat Transfer Vinyl

- Requires a cutting machine

- Uses solid colors rather than printed images

- Applied with a heat press or iron

- Extremely durable once bonded

HTV is widely used in logo branding, lettering, numbers, and simple graphic designs where clean edges and long-lasting results are essential.

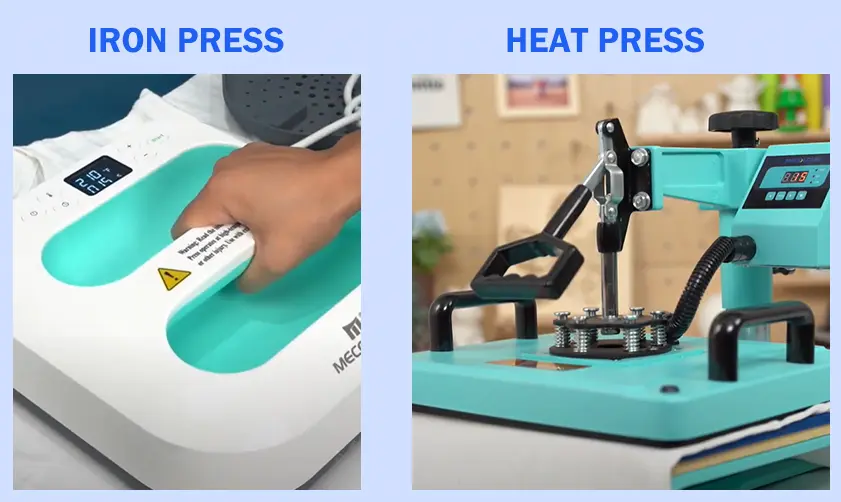

iron press and heat press

What Is Inkjet Transfer Paper

Inkjet transfer paper is a printable media designed to work with standard inkjet printers. Designs are printed directly onto the transfer sheet and then heat-pressed onto fabric.

Key Characteristics of Inkjet Transfer Paper

- Compatible with home and professional inkjet printers

- Ideal for full-color, photo-quality designs

- No cutting machine required

- Suitable for short runs and customization

Inkjet transfer paper is often chosen for photo prints, complex artwork, gradients, and multicolor images.

Heat Transfer Vinyl vs Inkjet Transfer Paper: Core Differences

Design Flexibility

HTV

- Best for single-color or layered designs

- Clean, sharp edges

- Limited for photos or gradients

Inkjet Transfer Paper

- Supports full-color images

- Excellent for detailed artwork

- Ideal for photographic designs

If design complexity matters, inkjet transfer paper offers unmatched flexibility.

Durability and Wash Resistance

Heat transfer vinyl durability is one of its strongest advantages.

- Can withstand 50+ wash cycles

- Resistant to cracking and peeling

- Maintains color integrity over time

Inkjet transfer paper durability varies depending on quality and finishing.

- Typically lasts 15–30 washes

- Requires correct pressing and curing

- Benefits from optional heat sealing

For long-term wear and commercial-quality garments, HTV clearly outperforms.

Fabric Compatibility

HTV Fabric Compatibility

- Cotton

- Polyester

- Cotton-poly blends

- Performance fabrics (with proper vinyl selection)

Inkjet Transfer Paper Compatibility

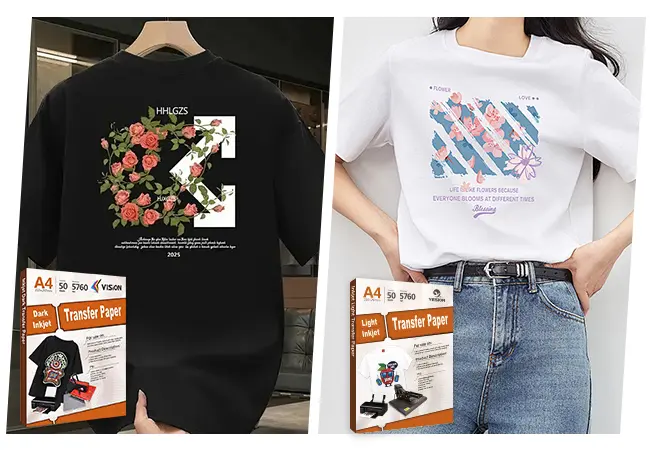

- Light fabric transfer paper for white or light garments

- Dark fabric transfer paper for black or colored garments

- Best on cotton or high-cotton blends

HTV offers broader fabric compatibility, especially for athletic wear.

Applications of Inkjet Transfer Paper

Production Workflow and Ease of Use

HTV Workflow

- Cut design on a vinyl cutter

- Weed excess vinyl

- Heat press onto fabric

- Peel carrier sheet

Inkjet Transfer Paper Workflow

- Print design on inkjet printer

- Allow ink to dry

- Heat press onto fabric

- Peel backing (hot or cold, depending on paper type)

For beginners without cutting machines, inkjet transfer paper is easier to start with.

Cost Comparison: HTV vs Inkjet Transfer Paper

Initial Investment

HTV

- Vinyl cutter required

- Heat press recommended

- Moderate startup cost

Inkjet Transfer Paper

- Inkjet printer only

- Heat press or iron

- Lower barrier to entry

Per-Design Cost

HTV

- Cost-effective for bulk production

- Minimal ink or waste

- Lower cost per unit over time

Inkjet Transfer Paper

- Ink consumption adds cost

- Higher per-sheet expense

- Best for short runs

For scaling businesses, HTV offers superior long-term cost efficiency.

Finish and Texture Comparison

HTV Finish

- Smooth or slightly raised texture

- Matte, glossy, glitter, metallic, flock, and reflective options

- Professional retail-quality appearance

Inkjet Transfer Paper Finish

- Softer hand feel depending on paper type

- Can appear film-like on dark fabrics

- More natural for photo prints

For bold branding, HTV delivers a cleaner and more premium look.

Color Accuracy and Vibrancy

HTV Colors

- Solid and consistent

- No fading when properly applied

- Limited by available vinyl colors

Inkjet Transfer Paper Colors

- Unlimited color range

- Dependent on ink

- Requires color management

When color accuracy and gradients are critical, inkjet transfer paper excels.

Time Efficiency and Production Speed

HTV

- Faster for repetitive designs

- Efficient for logos and text

- Ideal for batch production

Inkjet Transfer Paper

- Faster for one-off designs

- No cutting or weeding

- Slower drying and curing time

Production speed depends heavily on design type and volume.

Common Use Cases for Heat Transfer Vinyl

- Sports jerseys

- Company uniforms

- Tote bags

- Hats and caps

- Promotional apparel

HTV is preferred when durability, consistency, and professional appearance are required.

Common Use Cases for Inkjet Transfer Paper

- Custom photo T-shirts

- Personalized gifts

- Event merchandise

- Short-run promotional apparel

- DIY crafting projects

Inkjet transfer paper is ideal for creative freedom and customization.

Which Is Better for Small Businesses

For small apparel businesses, the decision between heat transfer vinyl vs inkjet transfer paper depends on business goals.

- Brand-focused, repeat designs: HTV

- Custom, personalized orders: Inkjet transfer paper

- High-volume production: HTV

- Low-volume, full-color designs: Inkjet transfer paper

Many successful businesses use both methods to cover different customer needs.

- Choose heat transfer vinyl for durability, professionalism, and bulk production

- Choose inkjet transfer paper for full-color creativity and custom designs

Understanding the strengths of each method ensures better results, happier customers, and more efficient production.

Related:

DTF Printing vs Heat Transfer Vinyl: Which is beneficial for your business?

Heat Transfer Vinyl vs. Screen Printing: Comparison

Heat Transfer Paper vs. Other Printing Methods: Pros and Cons