My answer is no, inkjet printers cannot do DTF printing, but we can convert DTF printers with inkjet printers.

I’m sure you’ve heard of DTF printing before because DTF technology is very popular right now. But you may not be familiar with how it works. Or you might confuse it with DTG printing.

DTF stands for Direct to film. This technique prints your design directly onto film and then uses a heat press to transfer it directly to t-shirts made of cotton, polyester or their blends, this technique transfers images, colors to lifelike on the image.

Although DTF printing appears to be a variant of transfer printing, it still requires a desktop inkjet printer that uses textile inks designed for DTF printing.

How do I print a DTF transfer?

A big advantage of this technique is that the white ink layer is printed at the same time as the color ink. This feature makes it a very easy alternative compared to other methods like white toner.

Also, to use DTF, you should know that valid formats for print designs are: eps, ps, pdf, bmp, tif, jpg, png, and psd.

What do I need to print a DTF transfer?

Now that you understand DTF printing, first understand what you need and how to use it, what it can bring you, so you know what equipment you need and how much investment your business needs.

What do you need to transfer a t-shirt?

First, we need a DTF printer converted from an inkjet printer, such as our Epson L800,Special Inks for DTF Printing: These very elastic inkjet inks prevent print cracks when the garment is stretched after printing.

DTF ink, also known as film transfer textile pigment inks, are used for printing on DTF film by DTG or DTF printers. DTF Ink is a new technology of garment thermal transfer – digital thermal transfer. DTF inks can be transferred to a variety of textiles and fabrics, as well as other substrates.

The DTF ink by VISION DTF printing factory is a water-based paint ink, which is a water-based ink. DTF ink is suitable for special digital printing of various EPSON printers, printed on white ink printing paper. DTF ink is dispersed on the surface of fabric, leather and other objects under high temperature heating.

DTF Film: It’s the surface on which you print your design, it’s a thin film.

DTF film (Direct Transfer Film) is a hybrid hot/cold peel. It’s a versatile solution that gives you vibrant colors and a premium finish. You can use it for any material (cotton, polyester, leather, canvas, t-shirts, pillows, hats, gloves, sneakers, phone cases, etc.)

The printed side of the DTF film is a matte coating that is opaque white. The back is uncoated matte with a clear sheen for easy identification.

DTF powder: It acts as a binder between the ink and cotton fibers. Our toners are available in white and black.

RIP software: The CMYK and white layers need to be printed correctly because, as mentioned, the printer has been modified to print in the correct order by itself.

Heat Press Machine: We recommend using a press with a vertically descending upper platen to make the curing process of the DTF film easier. Or you can also use a small iron, which is also very convenient.

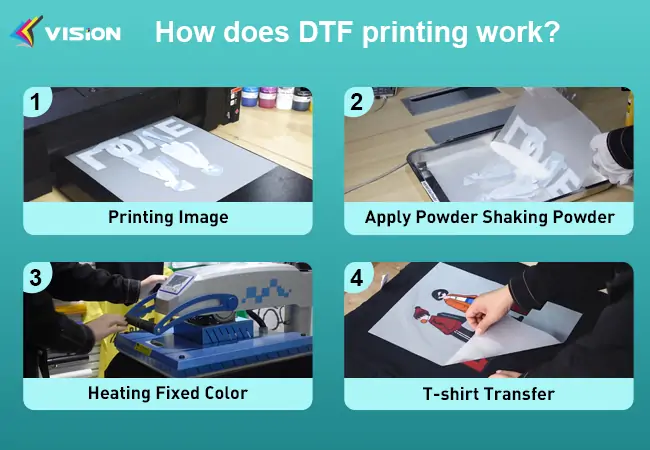

How does DTF printing work?

How does DTF printing work

The process is very simple and can be divided into the following steps:

1. Printing

2. Sprinkle with hot melt powder

3. Shake powder

4. Dry melting powder

5. Heat press

6. Peel off the film

7. Done

If you want to know more, please contact us, we are so glad to provide free samples and more videos for reference, waiting for your message.