Blog

Tips for Making Stunning Designs with Infusible Ink Transfer Sheets

Infusible Ink Transfer Sheets offer crafters and creators a unique opportunity to produce vibrant, permanent, and professional-level designs with infusible ink transfer sheets on a variety of surfaces. Unlike traditional iron-on vinyl, infusible ink becomes part of the material itself, delivering seamless finishes that don’t peel, crack, or fade. If you want to maximize the potential of these innovative sheets, mastering design techniques is essential.

This comprehensive guide explores the top design tips, project preparation steps, and advanced tricks to help you create eye-catching, professional-quality results with Infusible Ink Transfer Sheets.

What Makes Infusible Ink Unique?

Infusible ink is not like iron-on vinyl. Instead of sitting on top of your material, the ink becomes part of it. Through a process called sublimation, the ink transforms into gas under high heat and infuses directly into compatible surfaces such as polyester fabrics, ceramic, or specially coated blanks.

The outcome? Seamless, full-color designs that last as long as the material itself.

Choose the Right Compatible Surfaces

Not all blanks are suitable for infusible ink. For the best results, always select:

- Polyester-rich fabrics (at least 65%)

- Sublimation-compatible blanks (coated for heat transfer)

- Light-colored surfaces for vibrant ink transfer

Look for blanks labeled “infusible ink compatible” or “sublimation blank” to avoid faded or incomplete transfers.

Designs With Infusible Ink

Designs With Infusible Ink

Use High-Contrast Colors

Infusible ink is bold and vivid—but only when used on light or white backgrounds. Always opt for high-contrast designs. For example, bright reds, blues, and neons work beautifully on white polyester, while darker shades may appear muted or washed out on colored fabrics.

Keep It Simple for Small Projects

When working on small items like coasters or keychains, opt for minimalist patterns. Complex or intricate details may blur due to the gasification process. Bold shapes, clean lines, and geometric designs ensure clarity after pressing.

Leverage Repeating Patterns

Repeating designs like chevrons, stripes, polka dots, or florals work well for full-coverage transfers. You can layer them or rotate for a unique visual effect. These patterns are ideal for mugs, shirts, and tote bags where symmetry enhances the final product.

Add Personalization

Monograms, names, or quotes paired with vibrant backgrounds increase perceived value and appeal. Use bold fonts and contrasting layers to maintain readability and visual impact post-transfer.

Prepare Your Artwork with Precision

Mirror Your Design

Always mirror your image before cutting your Infusible Ink Transfer Sheet. Since the design is applied face-down, failure to mirror text or directional elements will result in reversed graphics.

Use the Correct Cutting Settings

If you’re using a cutting machine, select the Infusible Ink Transfer Sheet setting. The ink layer is delicate, so use light pressure to avoid cutting through the backing paper.

Weed with Care

Infusible ink doesn’t have a sticky backing like vinyl. Weed gently using tweezers or a weeding tool, especially around fine lines or curves, to avoid ripping the sheet.

Perfecting the Heat Press Process

Use the Recommended Heat Settings

Proper heat application is key. Always follow the manufacturer’s guide, but general settings include:

- Temperature: 385–400°F (195–205°C)

- Time: 40–60 seconds

- Pressure: Light to medium, even pressure

Always preheat your blank for 10–15 seconds to eliminate moisture, which can affect ink bonding.

Use Butcher Paper and Heat Resistant Tape

Place butcher paper over your design to protect your press and avoid ghosting. Use heat-resistant tape to secure the transfer in place—this prevents shifting that could cause blurring or double images.

Apply Even, Firm Pressure

Uneven pressure leads to inconsistent color. If using a handheld press, press down firmly and evenly across the surface. For larger items, a clamshell heat press is recommended.

Advanced Tips for Professional Results

Layering Infusible Ink Designs

Although you can’t layer sheets directly, you can use multi-step layering. Press one layer, let it cool, then add the next. This is great for adding shadows, highlights, or accent patterns.

Combine Infusible Ink with Other Mediums

Pair infusible ink backgrounds with iron-on vinyl top layers for a 3D effect. For example, press a watercolor infusible ink pattern first, then add gold glitter vinyl lettering.

Create Texture with Negative Space

Use cut-out shapes within your transfer sheet to let the blank surface show through. This technique creates a layered look without overlapping sheets.

Troubleshooting Common Issues

Faded or Dull Colors

- Ensure the blank is polyester-rich and light-colored

- Use high heat and proper time

- Pre-press to remove moisture

Blurry or Ghosted Images

- Use heat-resistant tape to secure the design

- Avoid moving the blank immediately after pressing

- Use even pressure

Transfer Didn’t Take

- Verify the surface is compatible

- Ensure temperature and time are adequate

- Avoid using cotton or low-poly materials

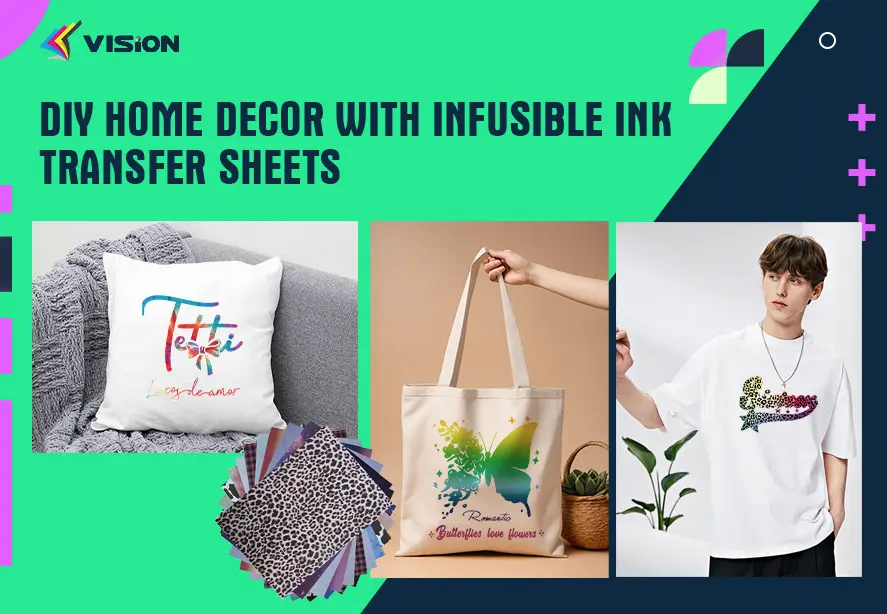

Inspiring Project Ideas Using Infusible Ink Transfer Sheets

- Custom t-shirts for family events or small businesses

- Branded tote bags with your logo or artwork

- Personalized coasters for holiday gifts

- Sublimated mugs with full-wrap patterns

- DIY puzzles and photo slates for keepsakes

The possibilities are endless when you combine creativity with high-quality materials and precise technique.

Conclusion

Mastering the art of designing with Infusible Ink Transfer Sheets unlocks a new level of customization and professionalism in your crafting. By choosing the right surfaces, crafting intentional patterns, and following best practices during the transfer process, you’ll consistently achieve vibrant, durable results that impress.

If you want to explore premium-quality infusible ink sheets, visit VisionSub’s Infusible Ink Transfer Sheets collection for more options.

Related:

How to use Infusible Ink Transfer Sheets with Cricut maker

The Ultimate Guide to Infusible Ink Transfer Sheets

What do you use Infusible Ink Transfer Sheets for?