Blog

How Can I Improve Sublimation Printing Quality?

Sublimation printing is one of the most powerful methods for transferring vibrant designs onto materials such as fabric, ceramics, metal, and more. However, achieving consistent, high-quality sublimation results requires attention to detail, precise control, and the right combination of materials and equipment. In this comprehensive guide, we’ll share proven techniques and expert tips to help you dramatically improve the quality of your sublimation printing, ensuring your designs come out vivid, sharp, and professional every time.

How to Improve Sublimation Printing Quality?

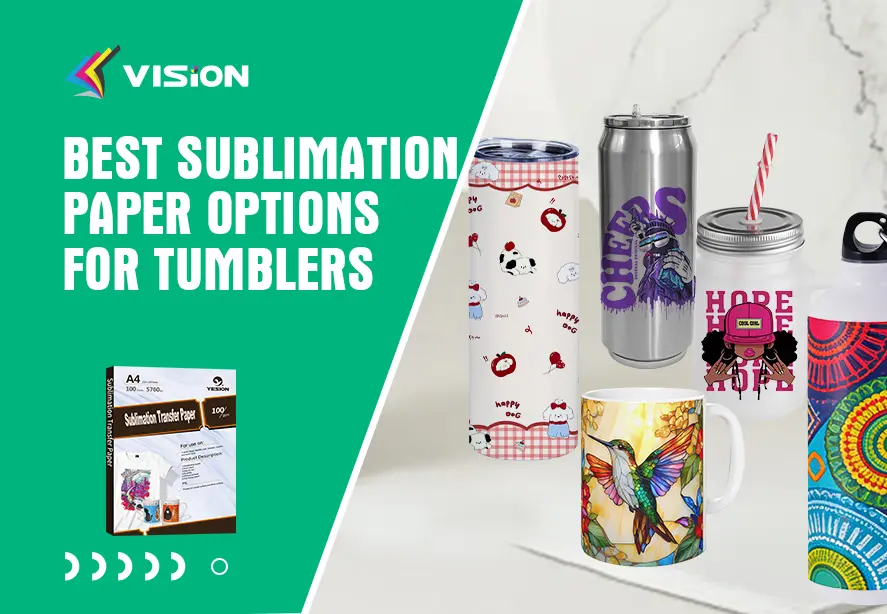

1. Use High-Quality Sublimation Paper

The foundation of high quality sublimation printing results begins with the right sublimation transfer paper. Cheap or low-quality paper can cause issues such as blurry images, color bleeding, and uneven transfers.

We recommend using premium sublimation papers that have a fast-drying coating and high ink absorption capacity. The best papers maintain crisp edges and vivid colors while minimizing ink waste.

Pro Tip

Store your sublimation paper in a dry, cool environment to avoid moisture absorption that can interfere with ink release during pressing.

2. Choose the Right Sublimation Ink

Not all sublimation inks are created equal. The ink formulation plays a major role in how vibrant and durable your prints will be. Always use original or certified sublimation inks that match your printer model and paper type.

High-quality inks deliver:

- Bright, consistent color output

- Accurate color matching across designs

- Long-lasting prints that resist fading and peeling

Avoid mixing different ink brands, as this can result in color inconsistencies and clogged printer heads.

sublimation ink and paper

3. Optimize Your Printer Settings

To maximize sublimation print quality, it’s essential to calibrate your printer settings correctly. Using the default print mode isn’t always enough — fine-tuning your settings can make a significant difference.

Recommended Adjustments:

- Print Resolution: Set your printer to the highest resolution (usually 1440 dpi or above).

- Color Profile: Use an ICC profile specifically designed for your ink and paper combination.

- Paper Type: Select “Premium Matte” or “Photo Paper” in your printer driver for optimal ink output.

- Mirror Image: Always enable mirror mode before printing your design.

Bonus Tip

Perform regular print head cleanings to prevent nozzle blockages that cause banding or uneven color distribution.

4. Ensure Correct Heat Press Settings

Even the best print will fail without the right heat press temperature, time, and pressure. Each material reacts differently under heat, so adjusting your press settings is critical.

| Material | Temperature (°C) | Time (Seconds) | Pressure |

|---|---|---|---|

| Polyester Fabric | 190–200°C | 45–60 | Medium |

| Ceramic Mugs | 180–200°C | 180–200 | Medium-Firm |

| Metal Plates | 190°C | 60–90 | Light |

| Mouse Pads | 190°C | 60 | Medium |

Avoid overheating, which can cause the print to appear dull or discolored, and underheating, which leads to incomplete transfers.

heat press transfer

5. Maintain Proper Pressure Balance

Inconsistent pressure during heat pressing often results in patchy or uneven transfers. To fix this, ensure:

- Your press platen is level across all corners.

- You apply uniform pressure according to the substrate.

- You use a heat-resistant foam pad or silicone mat to maintain even contact.

Testing pressure settings with small sample prints before mass production can help you identify the sweet spot for your machine.

6. Pre-Press and Prepare Your Substrates

Before pressing, always pre-press your materials for a few seconds to remove moisture and wrinkles. This ensures better ink penetration and reduces the risk of ghosting or hazy prints.

For Textiles

Preheat for 5–10 seconds to remove moisture.

For Hard Surfaces

Wipe the surface clean with isopropyl alcohol to remove dust and oils.

Moisture is the biggest enemy of sublimation. Even a small amount trapped in the material can cause fading, blurring, or uneven color distribution.

sublimation paper for mugs

7. Control Environmental Conditions

Temperature and humidity in your workspace significantly affect sublimation quality.

Keep your working environment at around 20–25°C (68–77°F) with humidity levels between 40–60%. Excess humidity can make the paper curl or cause colors to shift during pressing. A dehumidifier or air conditioner can help maintain optimal conditions.

8. Use Proper Design Files and Color Management

A common mistake in sublimation printing is using low-resolution artwork. Always use high-resolution images (at least 300 DPI) to prevent pixelation.

Additionally, color management through ICC profiles ensures accurate color reproduction between your design software and the final print.

Most printer and ink manufacturers provide free ICC profiles for download. Install and select the appropriate one in your design software (Photoshop, CorelDRAW, or Illustrator) for the most precise results.

9. Avoid Ghosting and Shadowing

Ghosting happens when the sublimation paper shifts during heat pressing, leaving behind a faint duplicate image. To prevent this:

- Use high-temperature heat-resistant tape to secure your paper in place.

- Ensure your heat press opens vertically, not in a swing-away motion that can cause sliding.

- Allow the substrate to cool completely before handling to prevent smearing.

10. Test and Document Your Process

Every sublimation setup behaves differently. The key to consistent improvement is testing, tracking, and refining your process.

Keep a printing logbook to record each project’s:

- Temperature, pressure, and time

- Paper and ink types

- Substrate material

- Color outcomes and issues

By comparing results, you can identify what combination yields the most vibrant, accurate, and lasting prints.

11. Regular Maintenance of Equipment

Consistent machine maintenance ensures you avoid sudden breakdowns or poor print performance. Clean your printer’s heads weekly, remove dust from your press plates, and check alignment regularly.

Replace any worn-out heat pads or damaged Teflon sheets, as they can cause hot spots and uneven pressure.

12. Choose Quality Blanks for Sublimation

No matter how perfect your settings are, low-quality blanks will ruin the final print. Always use sublimation-coated products designed for heat transfer.

For fabrics, choose 100% polyester or blends with at least 65% polyester content. For hard surfaces like mugs or keychains, ensure they have a polymer coating to accept the sublimation dye effectively.

sublimation textiles

Improving sublimation printing quality requires mastering a combination of premium materials, precise printer calibration, and disciplined heat press control. By applying these techniques—selecting the right paper, ink, and substrates, maintaining proper heat and pressure, and managing colors—you’ll consistently produce brilliant, durable, and professional-quality prints that stand out from the competition.

Related:

The Different Types of Sublimation Paper and Their Features

Knowing About The Best Sublimation Paper for T-shirts

What is best way to keep sublimation paper?