Blog

Mastering Dark Fabric Printing: Pro Tips for Exceptional Results

Printing on dark fabrics can be a challenging endeavor, but with the right approach, tools, and techniques, it becomes an art that yields vibrant, professional-looking results. Whether you’re producing custom T-shirts, hoodies, or tote bags, understanding how to perfect the dark fabric transfer process will set your creations apart in quality and durability.

Understanding the Unique Challenges of Dark Fabric Printing

Dark fabric printing poses different challenges compared to light fabric printing. Unlike white or light-colored garments, dark textiles require an opaque base layer to ensure that colors appear vivid and crisp. Without proper layering and material choices, the design may appear muted, uneven, or fade prematurely.

Choosing the Right Heat Transfer Paper for Dark Fabrics

One of the most critical decisions is selecting the correct heat transfer paper for dark fabrics. Not all transfer papers are created equal. For dark garments, opt for dark fabric transfer paper specifically engineered to block out the fabric color.

Key Features to Look For:

- High-opacity backing to prevent fabric color bleed-through

- Ink compatibility (inkjet or laser)

- Easy peel backing for smoother application

- Durability under multiple washes

Brands like Yesion, Vision offer high-quality dark transfer papers that professionals rely on for consistent results.

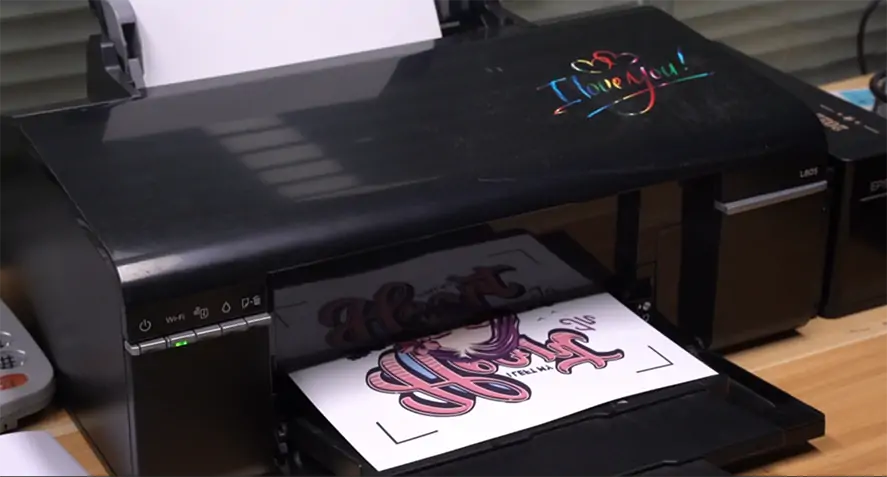

Design and Printing

Preparing the Design: Image Setup and Mirroring

Unlike light fabric transfers, dark fabric printing does not require mirror imaging. This is because the design is printed on the top surface of the opaque backing, not directly onto the fabric. When preparing the file:

- Set your resolution to 300 DPI or higher

- Use PNG format with transparent backgrounds

- Maintain rich blacks and vibrant colors for maximum impact

- Resize appropriately to match the print area without distortion

Utilize graphic design software like Adobe Illustrator, Photoshop, or Canva Pro to create pixel-perfect, layered designs.

Using White Ink or a White Base for Color Accuracy

When printing on black or dark garments, a white base layer is essential. This layer ensures that the vibrant inks sit on top of a neutral background, preventing color blending with the dark fabric.

For DTG (Direct-to-Garment) or DTF (Direct-to-Film) printing, white ink is printed first, followed by colored inks. In heat transfer methods, the transfer paper itself provides the white background, but ensure:

- The white base is not too thick, which can crack

- It adheres completely during pressing

- No edges are left unsealed

Optimal Heat Press Settings for Dark Fabrics

Heat pressing is the most critical step in achieving a flawless transfer. The pressure, time, and temperature must be tailored to the type of paper and fabric.

Recommended Settings:

- Temperature: 165°C to 180°C (330°F to 356°F)

- Time: 20 to 30 seconds

- Pressure: Firm, even pressure

- Peel Type: Cold peel (unless otherwise instructed)

Use a professional-grade heat press machine for even heat distribution. Avoid using household irons, which often lack the precision required.

heat pressing

Avoiding Common Mistakes in Dark Fabric Printing

Many printing issues can be traced back to a few common mistakes. Understanding these pitfalls can help ensure a flawless result every time.

Top Mistakes to Avoid:

- Skipping the lint roller: Dust and fibers create bubbles in the transfer

- Over-pressing: Causes ink bleeding and discoloration

- Not pre-pressing the garment: Moisture in fabric interferes with adhesion

- Ignoring test prints: Always test on scrap material before full runs

Being meticulous in setup and execution minimizes waste and maximizes quality.

Washing and Aftercare for Longevity

Proper post-transfer care ensures the durability of the printed design. Poor aftercare is the number one cause of early cracking or peeling.

Best Practices:

- Wait 24–48 hours before first wash

- Wash inside-out in cold water

- Use mild detergents

- Avoid bleach and fabric softeners

- Hang dry or tumble dry on low heat

Following these steps will keep prints vibrant for 50+ washes without visible degradation.

Advanced Techniques for High-End Dark Fabric Printing

As you gain confidence, exploring advanced methods can elevate your work to a professional commercial level.

Use of Teflon or Parchment Sheets

Place a Teflon sheet or parchment paper over the transfer during pressing to:

- Prevent sticking

- Distribute heat evenly

- Add a subtle matte or gloss finish

inkjet dark transfer paper

Layering Techniques

For complex multi-color designs, use registration marks and layered pressing with precision. This method is essential for large-scale logo or graphic work.

Combination of Vinyl and Print Transfers

Combine Heat Transfer Vinyl with printed transfers to add texture, dimension, or metallic effects to your artwork. This hybrid method creates stunning visual contrast and adds perceived value to your product.

Recommended Materials and Equipment for Beginners and Pros

Whether you’re just starting or scaling up, investing in the right equipment ensures consistent results and efficiency.

Starter Essentials:

- Inkjet printer with pigment inks

- Dark fabric transfer paper

- Basic heat press (30×38 cm)

- Cutting mat and scissors

- Lint roller

Final Thoughts: Quality Printing = Care + Precision

Mastering dark fabric transfers isn’t about luck—it’s about knowledge, the right tools, and disciplined practice. By investing in premium materials, following a precise process, and applying these pro-level techniques, anyone can create vivid, long-lasting prints that customers love.

Whether you’re customizing apparel for your small business, launching a print-on-demand line, or simply personalizing gifts, dark fabric printing mastery opens the door to creative, commercial success.

Related:

Choosing the Best Dark Fabric Transfer Paper

5 Easy Ways to Transfer a Pattern Onto Dark Fabric

Can I Use Heat Transfer Paper on Dark Fabrics?

Why Is My Dark Transfer Paper Not Sticking?