Blog

Why Your Heat Transfer Vinyl Is Lifting – How to Fix It Fast

If you’ve just spent time designing, cutting, weeding, and pressing your vinyl—and it starts lifting at the edges or peeling off after a wash—it’s frustrating. Heat Transfer Vinyl is a fantastic way to personalize apparel, bags, and fabrics, but when it doesn’t stick properly, it’s often due to avoidable mistakes. In this article, we’ll break down the top reasons of your heat transfer vinyl lifting, and give you quick, effective solutions to fix it fast and make it last.

Main causes and solutions for HTV lifting

1. Not Enough Heat or Pressure

❌ Problem:

Your vinyl isn’t bonding completely because your temperature is too low or pressure is too light. HTV needs the right combination of heat and pressure to activate the adhesive.

✅ Fix:

Check your press temperature with a thermometer or heat gun. Most HTV needs 305°F (150°C), but always follow the manufacturer’s specs.

Apply firm pressure, especially if using a manual press or EasyPress. For uneven surfaces like seams or zippers, use a pressing pillow.

2. Inaccurate Pressing Time

❌ Problem:

You didn’t press long enough—or pressed too long. Both can result in vinyl lifting or cracking later.

✅ Fix:

Use a timer for consistency. Most HTVs require 10–15 seconds of press time.

Recheck the pressing instructions for your specific HTV type (glitter, stretch, metallic, etc.).

3. Cold Peel vs. Hot Peel Mistake

❌ Problem:

You’re peeling the carrier sheet too early or too late, which causes the vinyl to lift.

✅ Fix:

Know your HTV type.

Hot peel vinyl should be peeled immediately after pressing.

Cold peel vinyl must cool completely before removing the carrier sheet.

htv peeling

4. Wrong Fabric Type

❌ Problem:

Certain fabrics, especially nylon or coated polyester, require special HTV or pre-treatment.

✅ Fix:

Make sure you’re using HTV compatible with the fabric. Use nylon-specific HTV for tricky materials.

Always test on a sample or corner before committing.

5. Residue, Moisture, or Fabric Softener

❌ Problem:

The fabric wasn’t clean or dry before application. Oils, dust, or softeners block adhesion.

✅ Fix:

Pre-wash garments without fabric softener.

Dry completely before pressing.

Wipe surface with a lint roller or cloth before heat application.

6. Uneven Surface or Mat

❌ Problem:

Pressing on uneven seams, buttons, or zippers results in poor adhesion on those spots.

✅ Fix:

Use a heat press pillow or teflon pad to level the pressing surface.

Avoid printing directly over bulky seams.

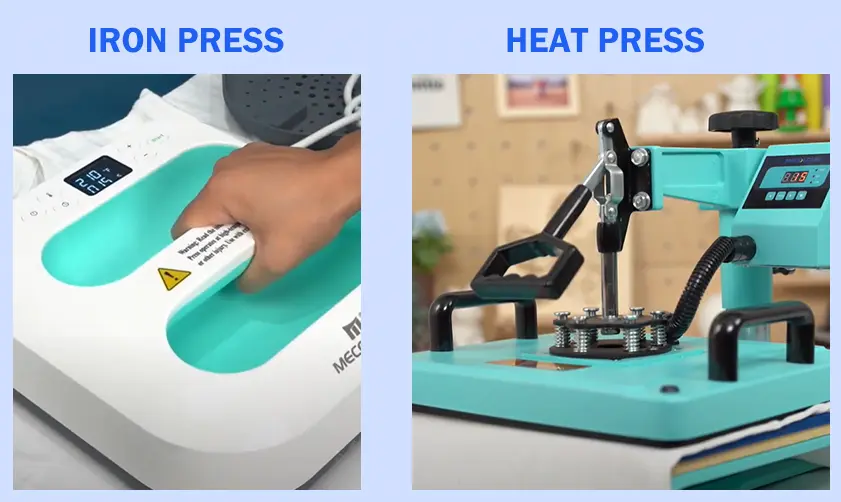

7. Using an Iron Instead of a Heat Press

❌ Problem:

A household iron can’t maintain even pressure and consistent heat, causing incomplete transfers.

✅ Fix:

Upgrade to a heat press or EasyPress for consistent results.

If using an iron, apply firm pressure, don’t move it around, and avoid steam.

iron press and heat press

8. Repeated Washing or Drying at High Heat

❌ Problem:

Even the best heat transfer vinyl can start lifting if garments are washed or dried too hot, too soon, or too often.

✅ Fix:

Wait at least 24 hours before washing newly pressed HTV.

Wash inside out in cold water and air dry or tumble dry on low.

Avoid harsh detergents or bleach.

Bonus Tip: Repress and Salvage Lifting Vinyl

If your design is starting to lift, all is not lost. Here’s how to save it:

Quick Fix:

Place a teflon sheet or parchment paper over the lifting vinyl.

Repress at the correct temperature and pressure for 5–10 seconds.

Let it cool (if cold peel), then press again with more pressure if needed.

For small areas, use a heat-resistant iron tip tool or mini iron to touch up corners.

Preventing HTV Lifting in the Future

| Step | Action |

| Check specs | Always follow the HTV brand’s instructions |

| Preheat fabric | Remove moisture by pressing for 5 seconds before applying |

| Use correct temperature | Use a thermometer or digital control |

| Apply firm pressure | Especially important for cotton and blends |

| Test small first | Always test new materials before full application |

Heat Transfer Vinyl lifting is a common issue, but one that’s easy to prevent and fix with the right tools, knowledge, and preparation. Pay attention to temperature, pressure, and timing, and your vinyl will stay put—even through washes and wear. Investing in quality tools and following your HTV’s exact specifications will ensure lasting, professional results every time.

Related:

How to Prevent Peeling and Cracking with Heat Transfer Vinyl?

What fabric is best for heat transfer vinyl?

9 Do’s and 9 Don’ts of Layering Heat Transfer Vinyl