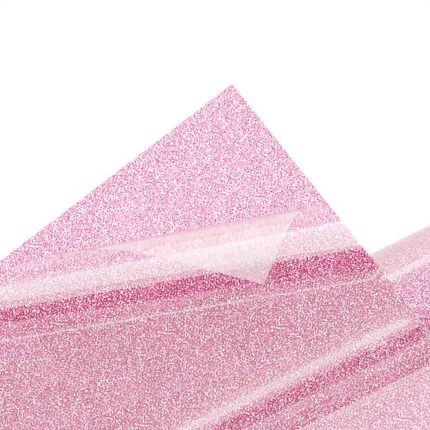

This Silicone PU heat transfer vinyl has a fluorescent pink front side and a yellow back side, and is also soft to the touch. The fluorescent pink color can add a bold and eye-catching element to designs.

The HTV vinyl has the ability to achieve a three-dimensional effect, which can add depth and texture to designs. It can also achieve a double color effect, allowing for more creative and visually interesting designs. This can be achieved by layering the vinyl in a specific way to create the appearance of two different colors.

Overall, the combination of the bright fluorescent pink color, soft texture, the ability to create three-dimensional effects, and the ability to achieve a double color effect make this type of Silicone PU heat transfer vinyl a popular choice for adding visual interest and texture to a wide range of garments and promotional products.

How to use Silicone PU heat transfer vinyl

Design: Create or obtain the desired design for your project. The design must be in vector format, as this will allow for accurate cutting of the vinyl.

Cut: Use a vinyl cutter to cut the design out of the Silicone PU heat transfer vinyl. Be sure to adjust the settings on your cutter to match the thickness of the vinyl you are using.

Weed: Remove any unwanted vinyl from the design using a weeding tool. This process is called “weeding” and is essential for achieving a clean final product.

Prepare textile item: Prepare the textile item by washing and drying it to remove any dirt or debris that may interfere with the vinyl’s adhesion.

Heat press: Use a heat press to transfer the vinyl design onto the textile item. Set the temperature and pressure settings on your heat press to the recommended levels for your vinyl type and the textile item you are using. Place the vinyl design onto the textile item, cover it with a sheet of parchment paper, and press for the recommended time.

Peel: Once the pressing is complete, peel the transfer paper from the vinyl design while it is still warm.

Finished product: Your custom design should now be successfully transferred onto the textile item.