Blog

DTF Transfer Film for Textiles: Everything You Need to Know

Direct to Film (DTF) technology has revolutionized fabric decoration, offering a versatile, high-quality, and cost-effective method for textile printing. If you’re in the custom apparel business or exploring advanced printing techniques for fabrics, understanding DTF transfer films is crucial to achieving professional results. In this guide, we cover every detail you need to master DTF transfer film for textiles, from composition to application, machine compatibility, and optimization tips.

What is DTF Transfer Film for Textiles?

DTF transfer film is a specially coated PET film designed to receive DTF ink and hot melt adhesive powder. Unlike sublimation, which requires polyester, or screen printing, which involves lengthy setup, DTF is suitable for a wide range of fabrics, including:

- Cotton

- Polyester

- Blends

- Silk

- Denim

- Nylon

The film acts as a carrier, holding the printed design until it’s transferred to fabric through a heat press. Its anti-static and high-release properties make it ideal for clean and easy transfers.

Benefits of DTF Transfer Film for Textiles

1. Broad Fabric Compatibility

One of the top advantages of DTF transfer film is that it allows printing on both light and dark fabrics without needing a pre-treatment process. You can decorate everything from cotton t-shirts to nylon sportswear with exceptional results.

dtf printing on light fabric

2. Vivid, Durable Prints

The ink sits atop the fabric rather than being absorbed into it. When cured with adhesive powder, it bonds tightly, delivering vibrant colors, sharp details, and superior wash resistance—even after 40–50 wash cycles.

3. No Weeding or Cutting

Unlike vinyl, DTF doesn’t require manual weeding. The design is printed digitally and applied in one press. This not only saves time but also allows for ultra-fine details and gradients, which are difficult with HTV or screen printing.

Types of DTF Transfer Films

1. Hot Peel vs Cold Peel Films

- Hot Peel DTF Film: Allows you to peel the film immediately after pressing. Ideal for high-speed production.

- Cold Peel DTF Film: Requires cooling before peeling. Offers slightly better finish quality and is more forgiving for new users.

2. Matte vs Glossy Finishes

- Matte Film: Produces a soft-touch, professional look, perfect for fashion garments.

- Glossy Film: Adds a bit of shine, often preferred for promotional t-shirts and logos.

3. Single-Side Coated vs Double-Side Coated

- Single-Side Coated: Coating on one side for ink reception.

- Double-Side Coated: Anti-slip layer on the reverse to prevent feeding issues in printers.

How to Use DTF Transfer Film for Textiles

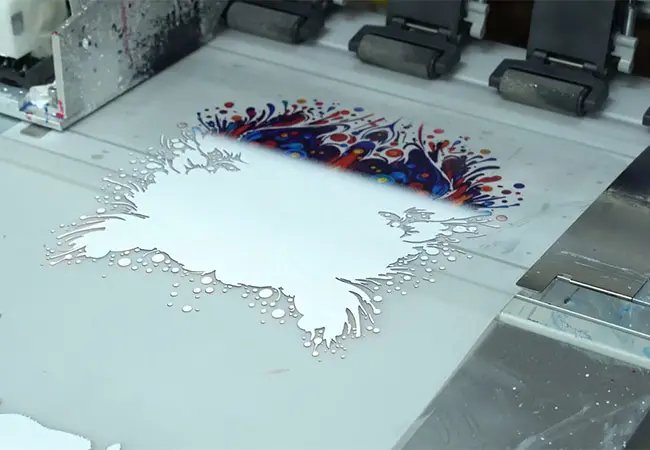

Step 1: Print the Design

Using a DTF printer, print your CMYK + White design directly onto the coated side of the film. Always print the white underbase after the colored image for better opacity and contrast.

dtf film printing

Step 2: Apply Adhesive Powder

While the print is still wet, sprinkle DTF hot melt powder evenly across the design. Shake off the excess. This powder ensures the ink bonds to the fabric during pressing.

Step 3: Cure the Powder

Using a DTF oven or a heat press in hover mode (without direct contact), cure the powder until it melts and forms a uniform, crystalline surface—usually at 120–160°C for 2–3 minutes.

dtf curing oven

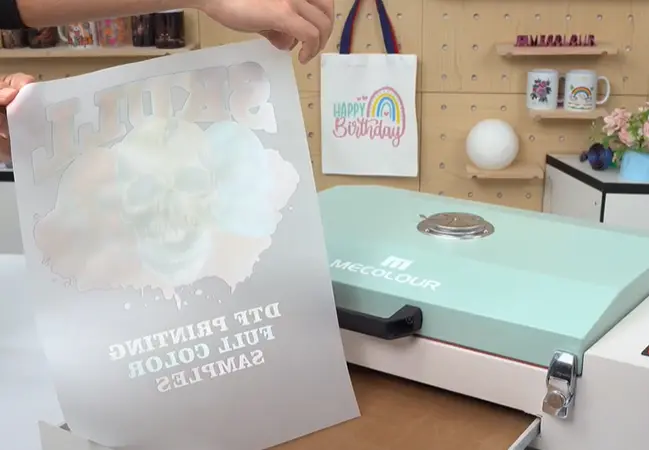

Step 4: Transfer to Fabric

Place the film face down on the textile and press at 150–165°C for 15 seconds with medium pressure. Follow film-specific instructions for peel timing (hot or cold).

heat press transfer

Step 5: Optional Second Press

For enhanced durability and finish, a post-press (3–5 seconds with a Teflon or parchment sheet) helps embed the print into the fabric.

DTF Film Care and Handling Tips

Storage Recommendations

- Store in a cool, dry environment (15–25°C)

- Avoid humidity and direct sunlight

- Keep films in their original packaging to prevent dust or debris

Printing Precautions

- Ensure the film is free from moisture before printing

- Use lint rollers to clean the film if necessary

- Handle by the edges to avoid oil transfer from hands

Heat Press Calibration

Regularly check your heat press for accurate temperature and even pressure. Uneven heat distribution can cause improper curing or poor transfer quality.

Troubleshooting DTF Film Issues

| Issue | Cause | Solution |

|---|---|---|

| Ink smudging or bleeding | Film too moist or incompatible ink | Use compatible DTF ink; dry environment |

| Poor adhesion to fabric | Insufficient powder or wrong temperature | Apply powder evenly; adjust temp/time |

| Cracked prints after washing | Low pressure or no second press | Increase pressure; apply second press |

| Film sticking to garment | Peeled too early on cold peel film | Let it cool before removing |

Compatible Printers and Inks

DTF films work best with modified Epson i3200, XP600, or L1800 printers. Use pigment-based DTF inks and ensure you regularly shake the white ink tank to avoid clogging. Paired with the right RIP software, you can achieve precise color control and white ink layering.

Sustainable Printing with DTF Films

Modern DTF films are often PVC-free and environmentally safer than traditional plastisol screen prints. They produce minimal waste and reduce the use of water, making them ideal for eco-conscious textile printing operations.

Why Professionals Prefer DTF Film

- Faster turnaround for custom orders

- Full-color, high-resolution prints on-demand

- Low setup costs for small batch or personalized products

- Expandable across markets: fashion, uniforms, home textiles, and promotional merchandise

Where to Buy Quality DTF Transfer Film

To achieve consistent, professional results, it’s crucial to buy from a reliable supplier that offers tested, high-release films with stable coating and uniform quality. Explore Vision Sub’s DTF Film collection for a wide range of products optimized for textile use.

Final Thoughts

DTF transfer film for textiles is a game-changer for garment decorators and print entrepreneurs. It merges quality, efficiency, and versatility into one streamlined process—perfect for today’s dynamic customization market. Whether you’re producing fashion lines, team apparel, or promotional items, DTF printing with the right transfer film ensures your designs stand out and last.

Related:

Choosing the Best Fabric for DTF Printing

Top Tips for Vibrant Colors in DTF Printing

What kind of printer and supplies are needed for DTF transfers?

How to use DTF Printing Film?